Comprehensive import of work order data

Introduction

The document describes the mechanism for importing comprehensive information specifying work orders in the system into the AMAGE system. This data includes basic information about orders, but also attachments/documentation facilitating the implementation of work, material lists necessary for their execution and the history of work performed.

The document describes import mechanisms and their use in order to fully import data into the system from various sources, but in total constituting complete information necessary to achieve a specific business goal. The tutorial does not describe in detail the functions of the importer mechanisms and individual windows. Please refer to the user manual for the basic user interface.

Principle of operation

Our goal is to import data from various areas of the company’s business systems into the AMAGE system. Let’s call them collectively the ERP system, but it is not necessary to have this data in one system.

Usually, for proper operation we need:

-

employee data - employees will log in to the system, but we also need data of employees who, even though they do not log in to the system, still exist in some way, e.g. they are members of executive teams, of which only their foreman has access to the system.

-

data of supervised elements - resources - these are objects on which business functions are performed. Whether they are devices, machines or construction elements, each of them has its own data, parameters and appropriate categorization of type and manufacturer.

-

assortment/type dictionaries - they can define resources but can also be used in ordering, delivery and warehouse modules as countable elements without specific representation as resources in the system.

-

work orders - orders that group activities to be performed into work units. They may be related to the assortment (what needs to be ordered, delivered) or specific resources (what needs to be built, installed, operated). For this we need additional imports of resources or types related to work orders - they will create material plans or lists of related resources in the system.

-

deliveries, warehouse documents - we can either use existing documents from the ERP system and transfer them to the AMAGE system in order to achieve data completeness or use this mechanism to import delivery documents issued by our subcontractors or suppliers.

The entire set of data mentioned above allows you to enter a significant amount of information into the system and use this data in individual field modules, e.g. supervision, service requests or inspections.

| The next stage of automation is to include the imports described above in the integration mechanism. The system can automatically download such files from specific sources (email, ftp, server directory) and use the import schemes (templates) specified in this tutorial. Here let’s focus on the definition of basic structures and import templates. |

Let’s go through all the import mechanisms in the order described above.

Importing users

We import users↓users. The XLS/CSV sheet contains user data, login, email, phone number and other data.

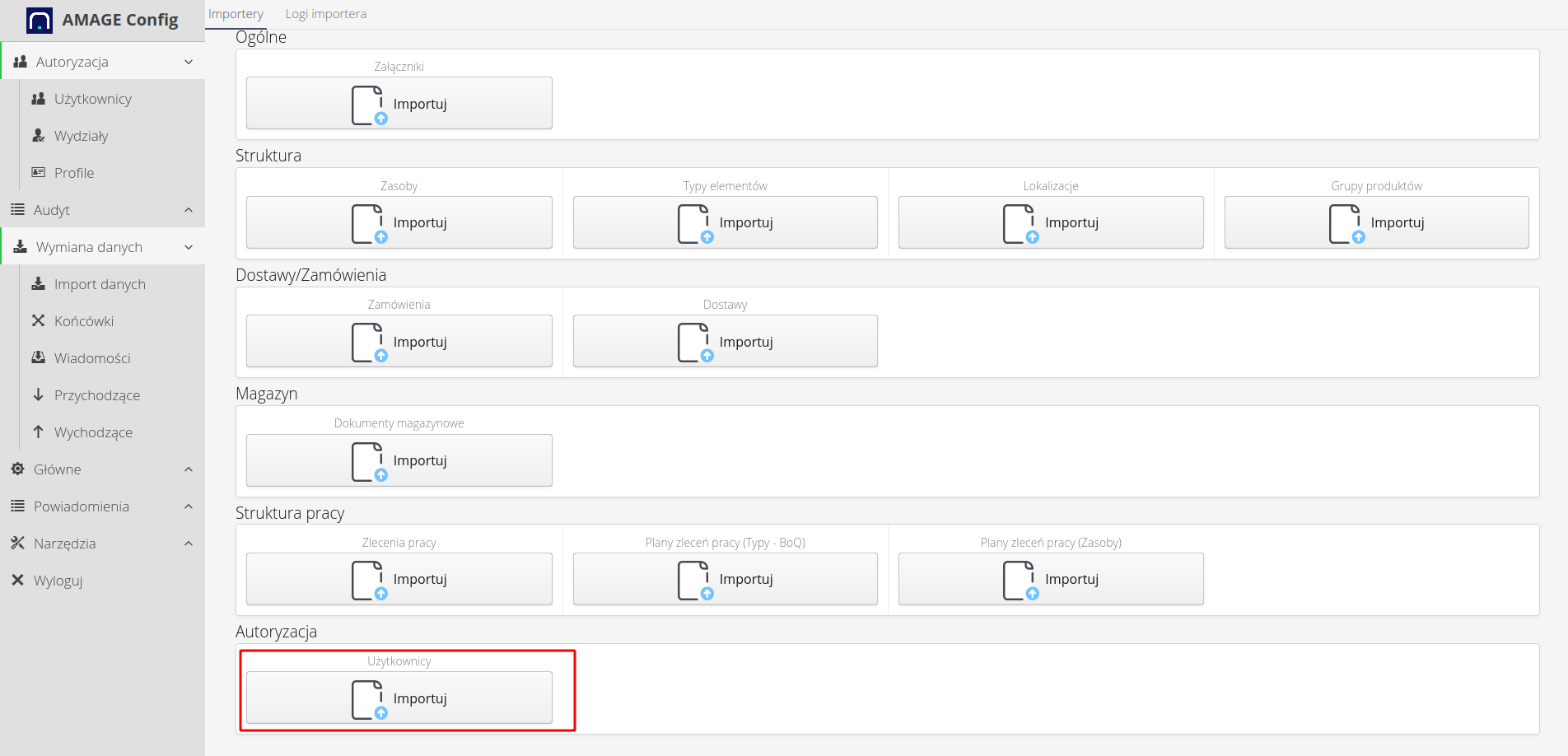

We select the import mechanism from the list of available importers.

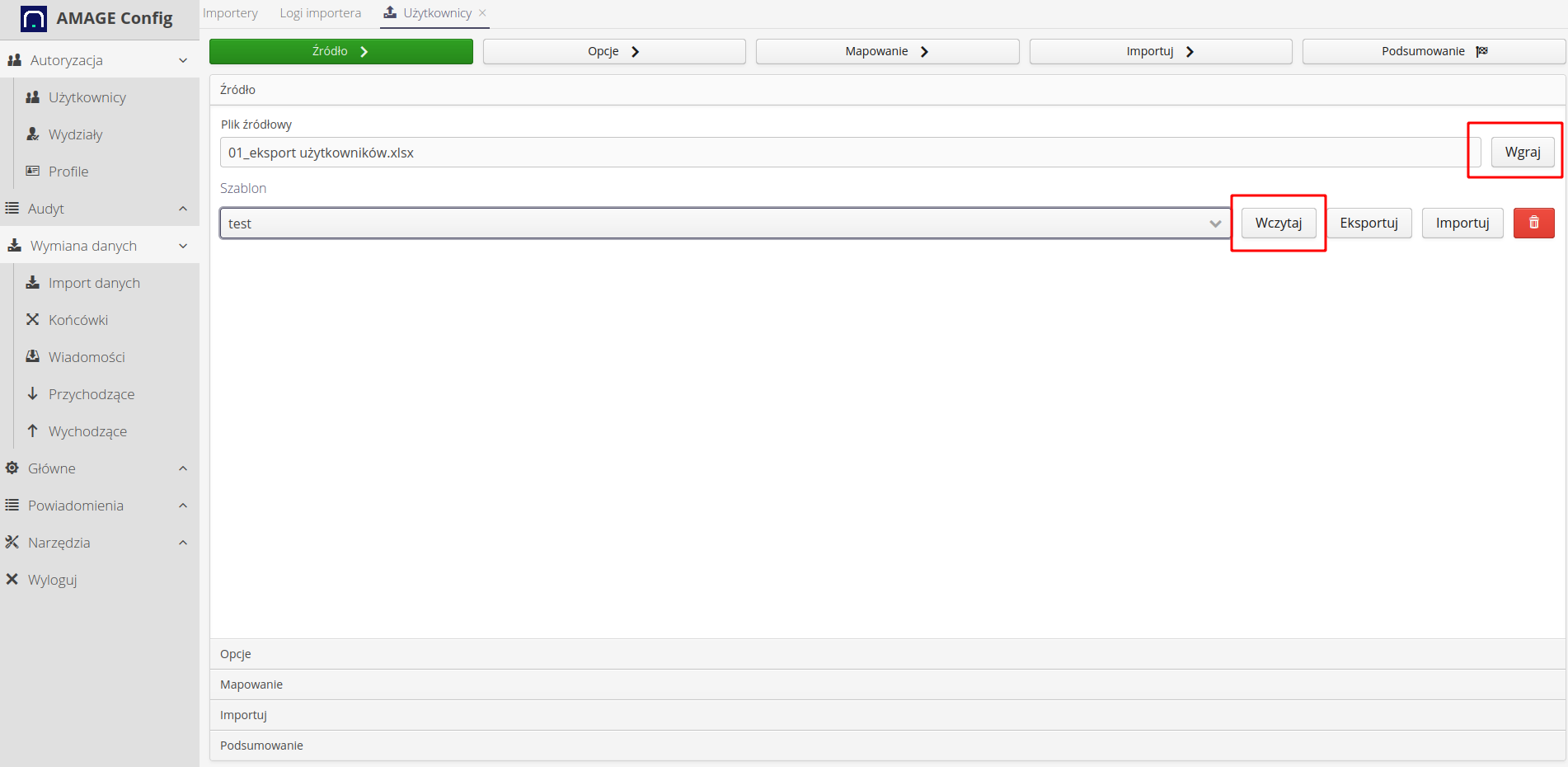

We select the file to be imported and, if we have already gone through these steps, the mapping template we have. If we don’t have it, we create it in the next steps.

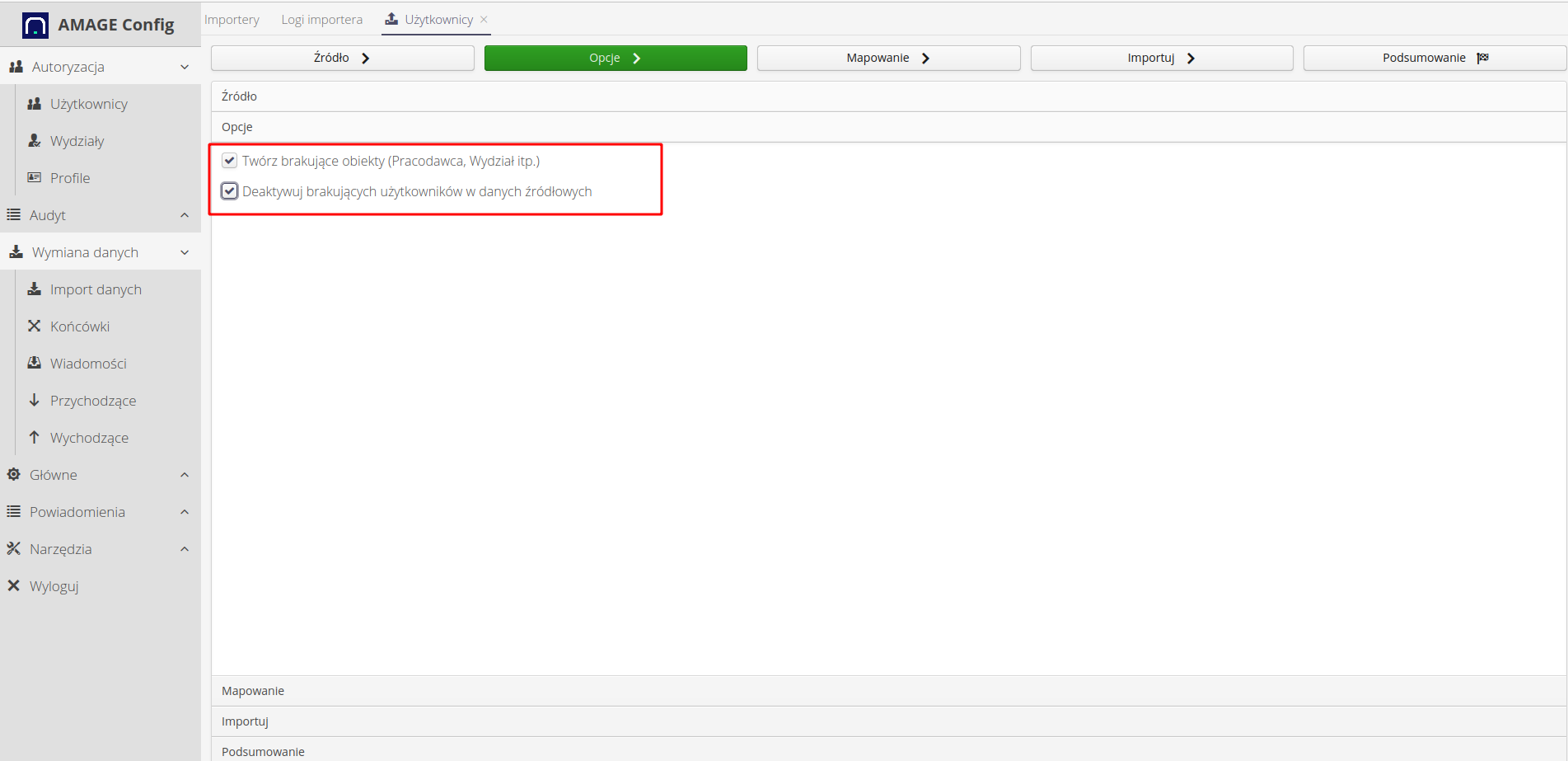

We define the import parameters. Each importer has its own specific parameters and behaviors. Here we have available:

-

add departments, employers - when importing, we automatically add/create the necessary additional records - departments, employers, etc.

-

deactivate missing employees - we treat the import file as the only data source and users who do not appear there are automatically deactivated in this system.

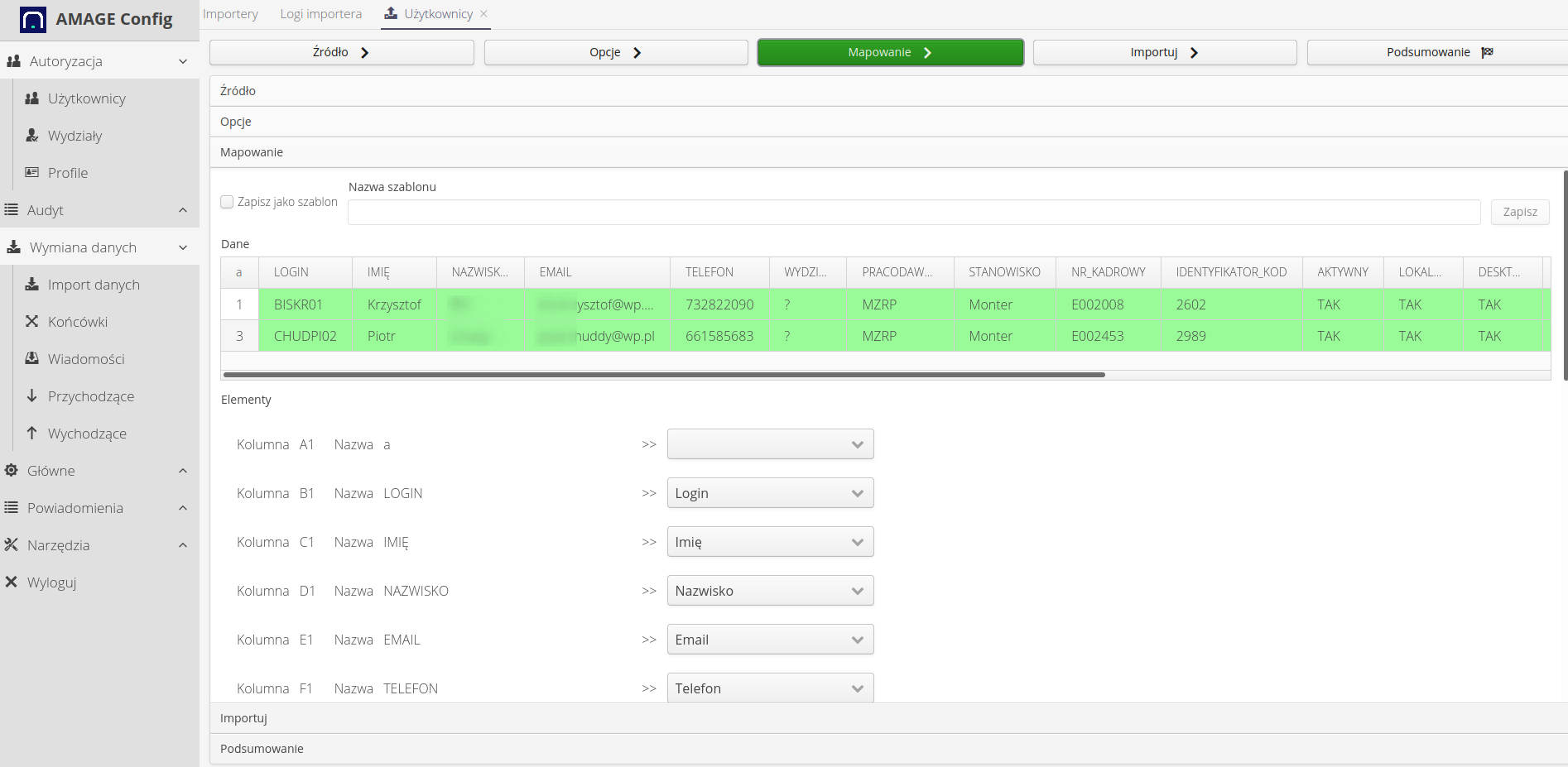

Then we define the fields and their meaning in the imported file. Here we can also save all previously defined data in the template under a specific name. We will be able to use it in subsequent imports or to automate the process.

We import. Employees/users are in the system.

Importing types

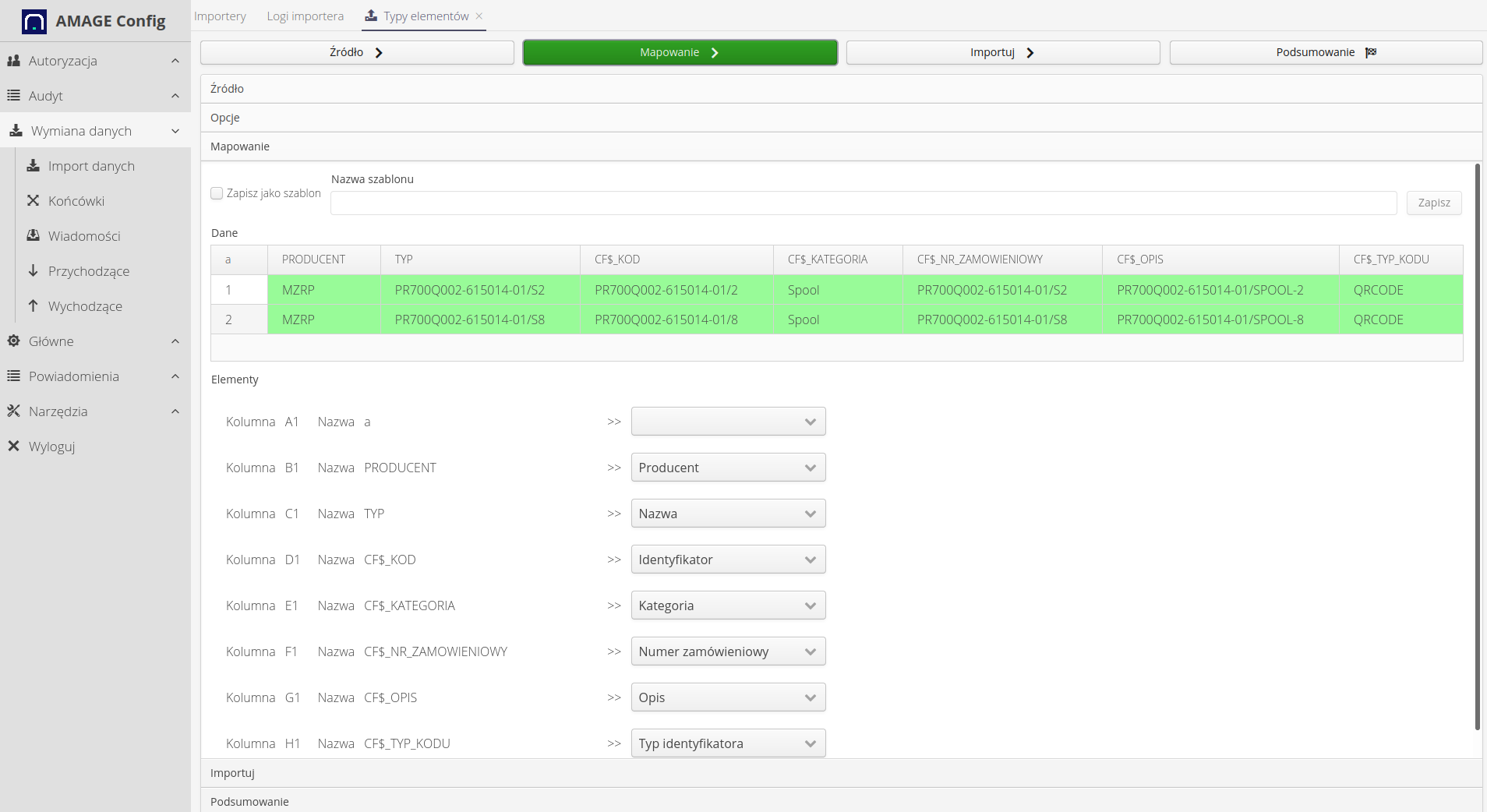

We move on to importing the assortment - element types. We usually have this data from the ERP system, from the warehouse or ordering module. We can also import data provided by our subcontractors.

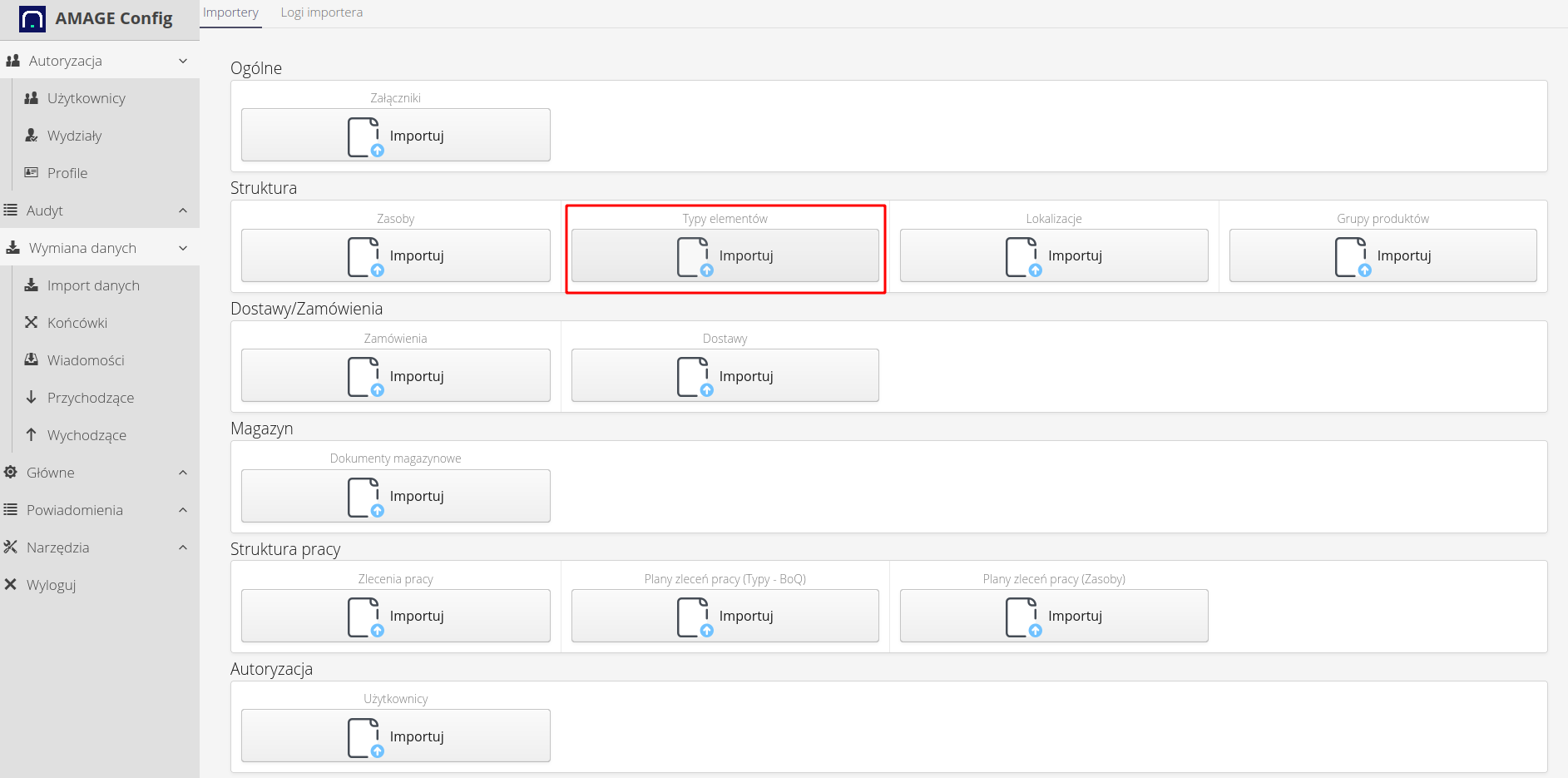

We select the importer from the list.

Let’s define field mapping and their meaning

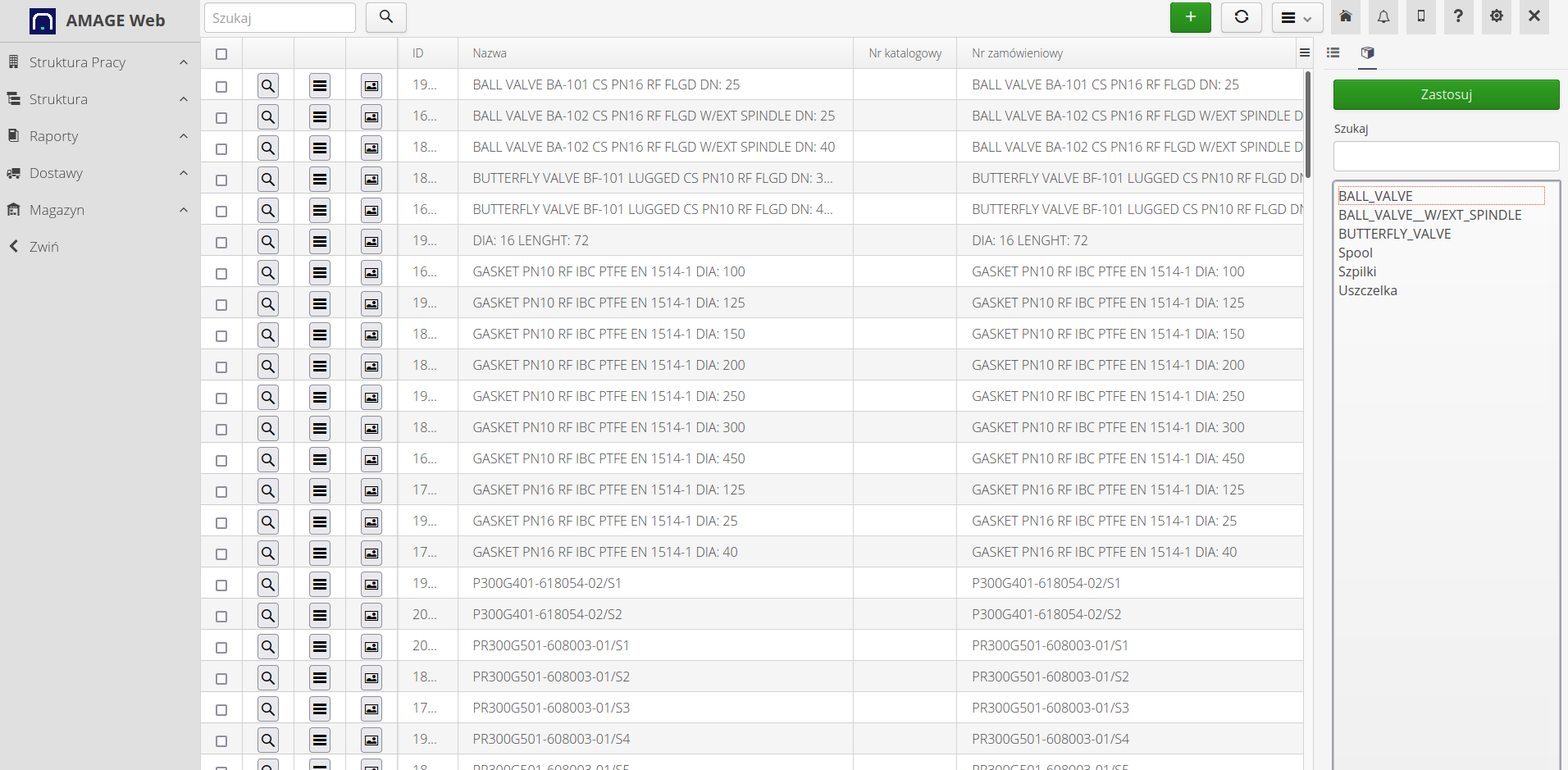

We import data. An example result of imported data with the division of the product range into categories is presented below.

Let’s move on to importing resources.

Resource import

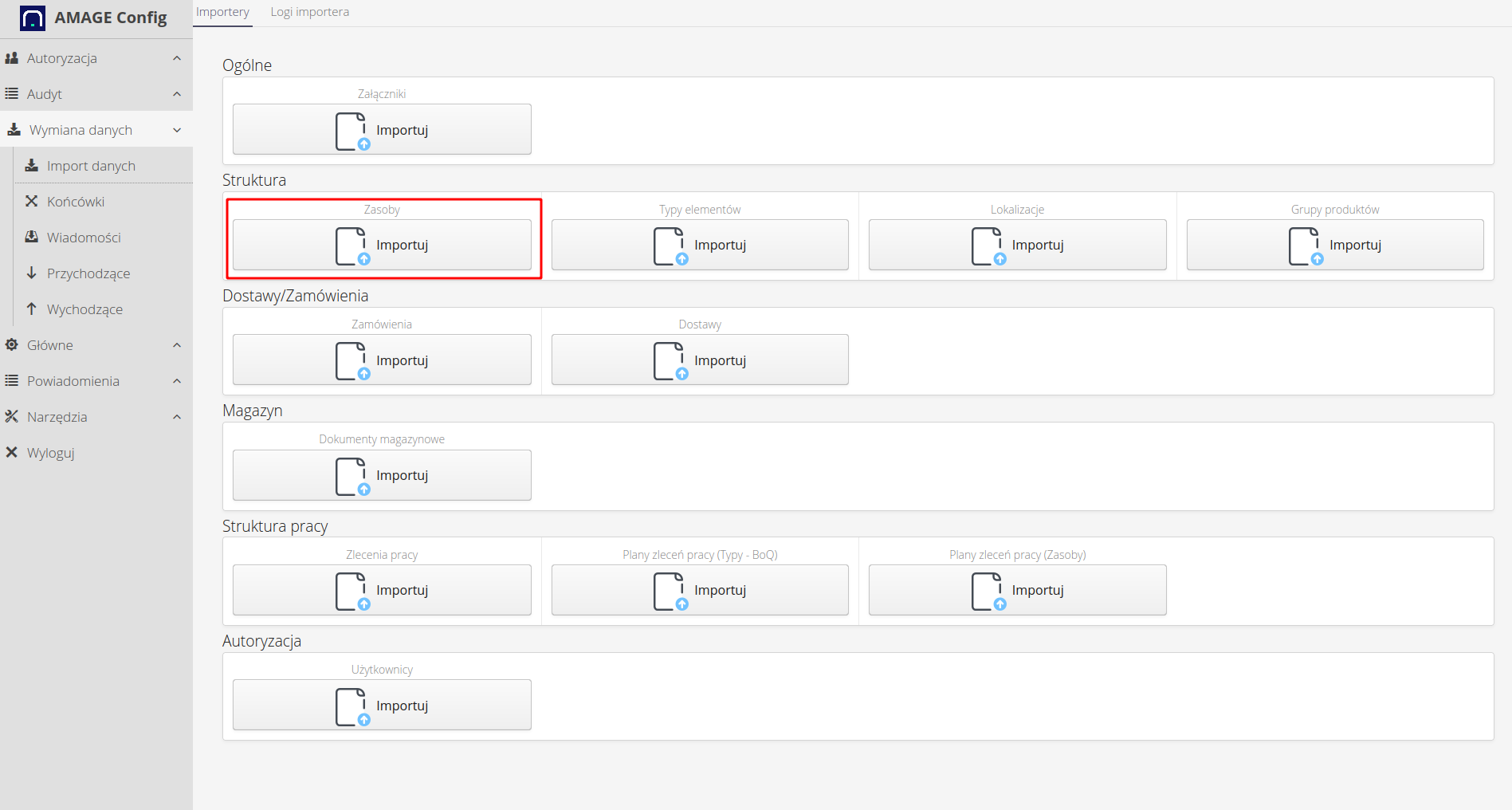

We select the resource importer from the list.

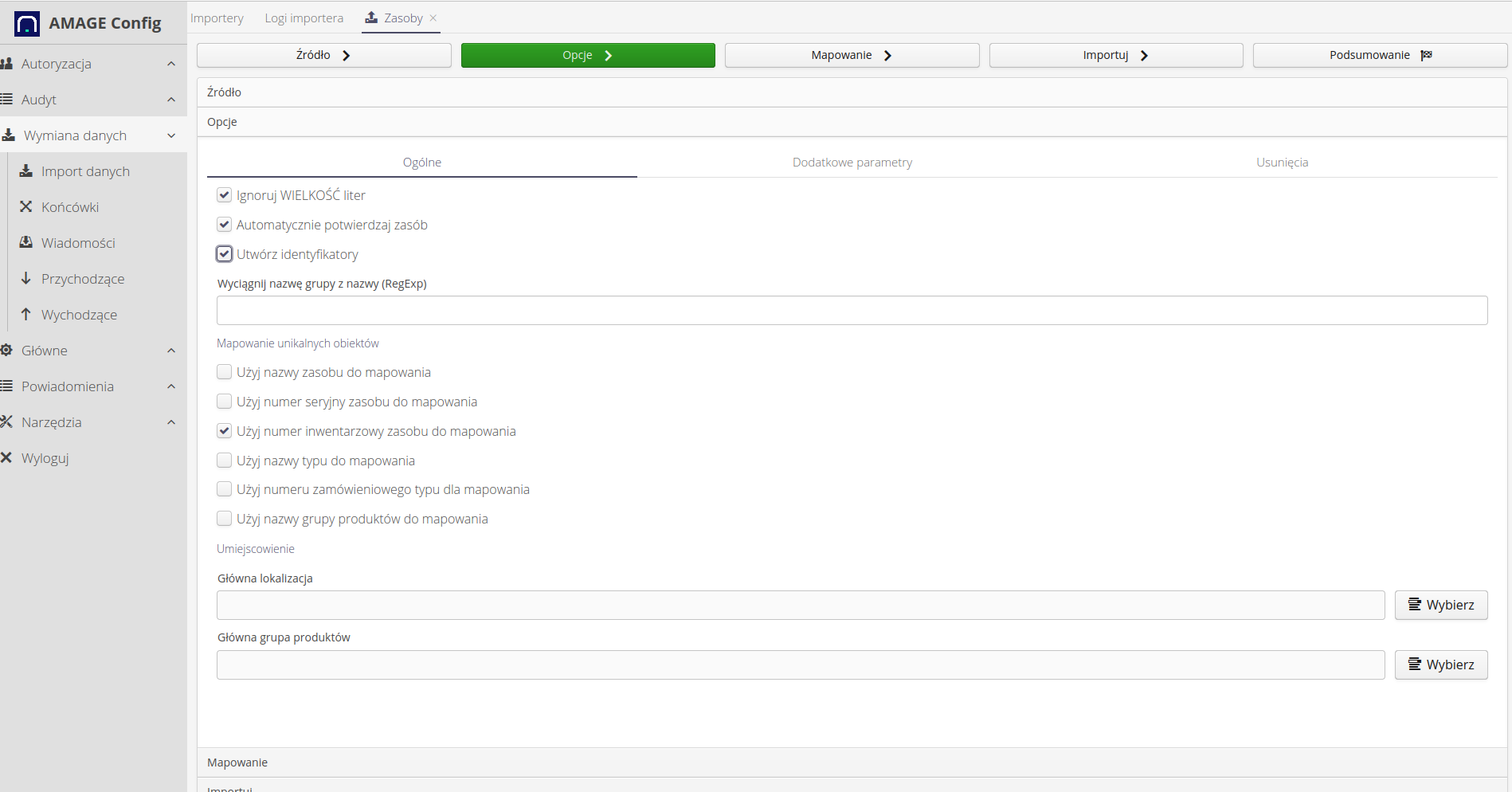

We define additional information and parameters. ATTENTION. The importer has an extensive parameter panel and please refer to the user manual for additional information about the meaning of individual parameters.

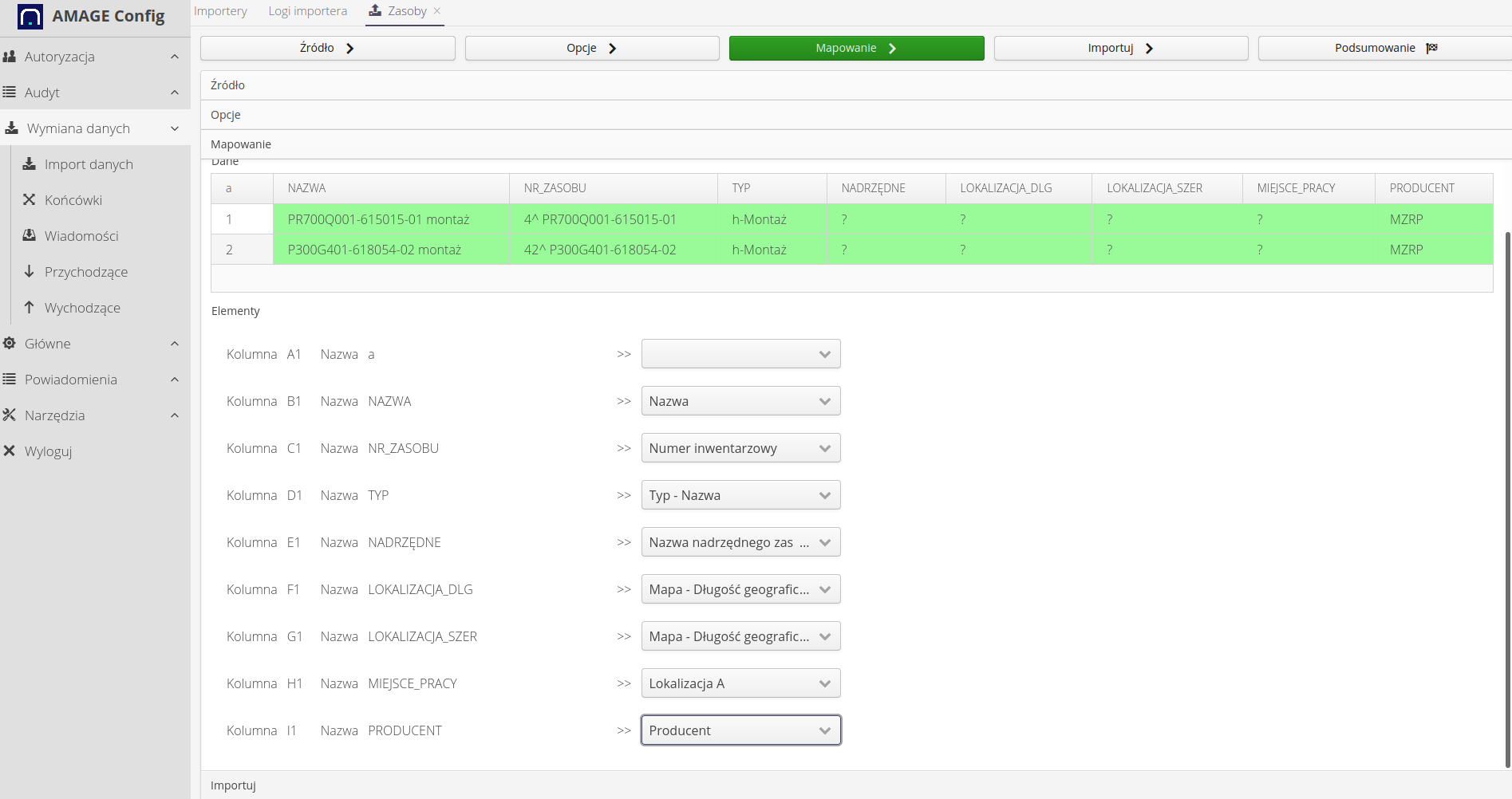

We define field mapping and their meaning.

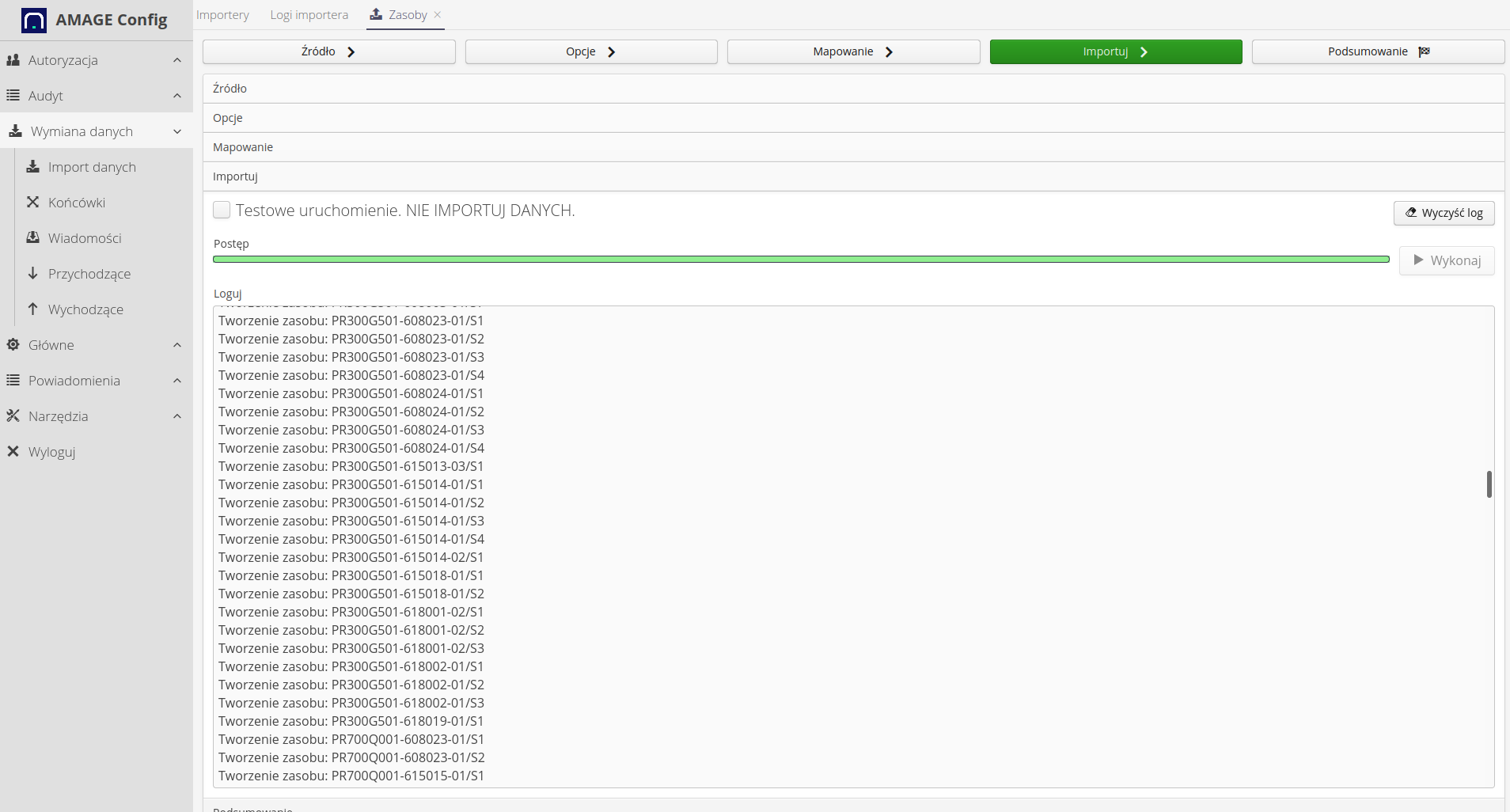

We import data. In the import progress view, we receive a visual report of the activities performed and any errors.

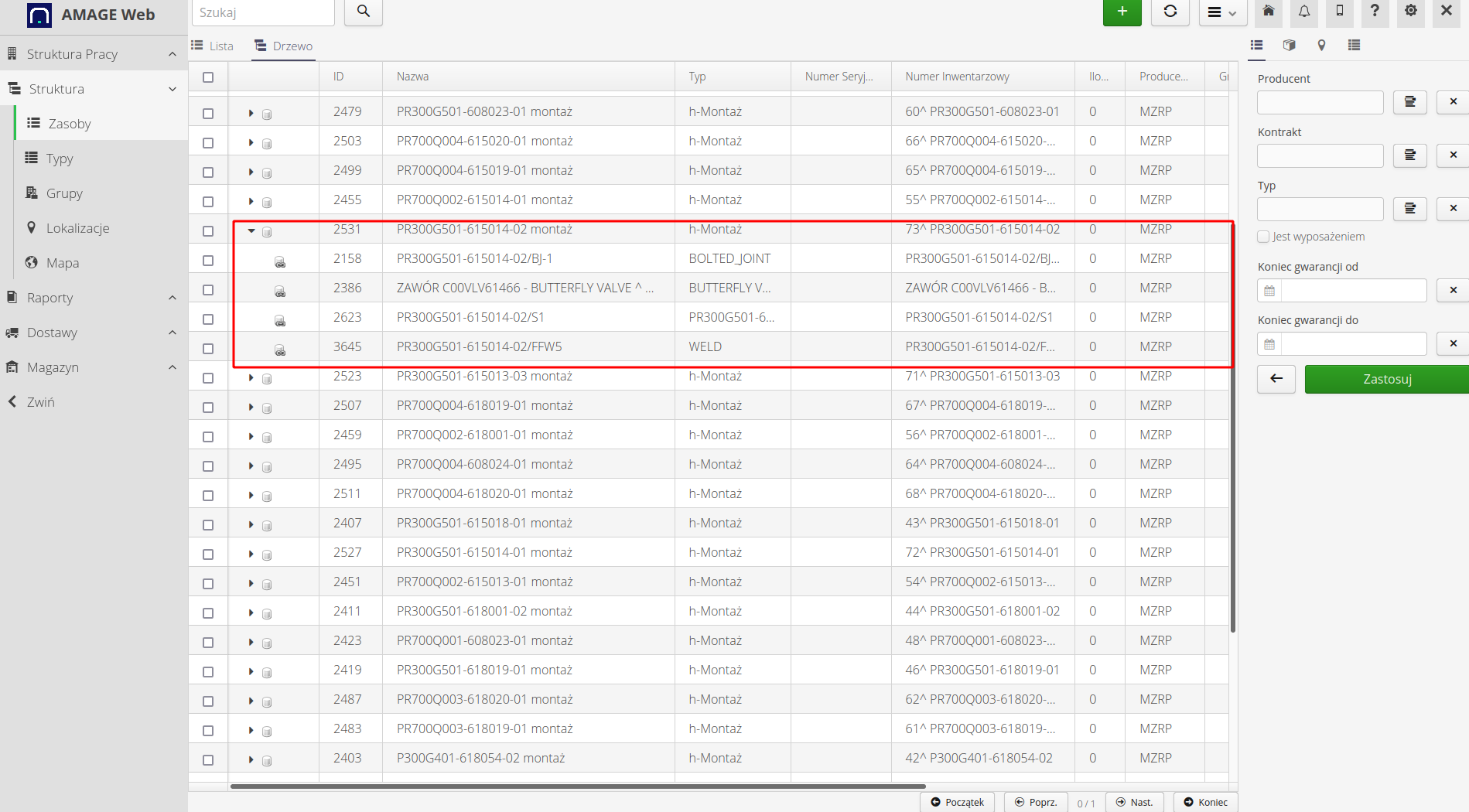

The end result is imported resources in the system along with their association in trees and appropriate categorization with element types.

We have a ready data structure on which we can work. Now let’s import the to-do list.

Work orders

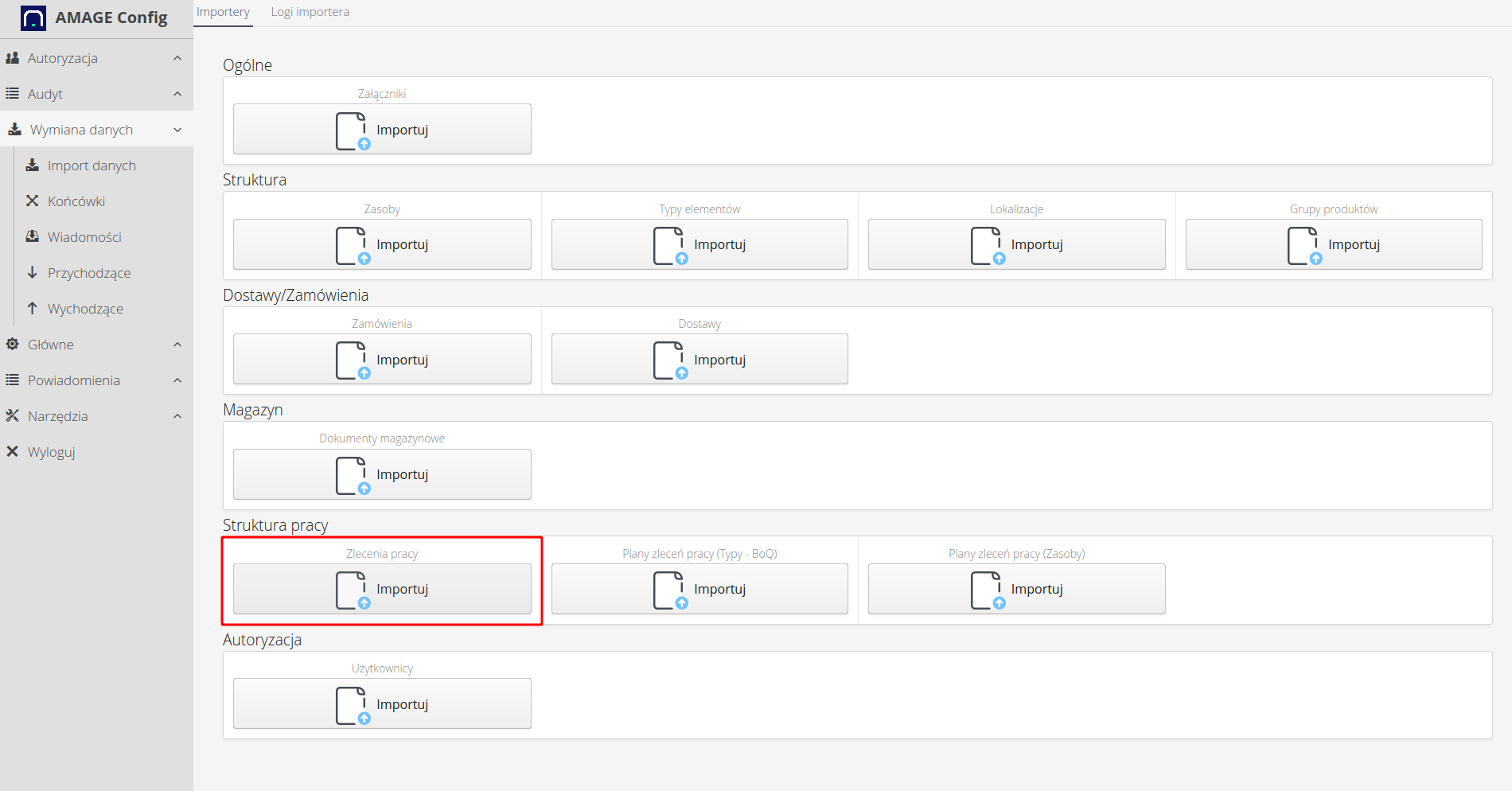

We select the work order importer from the list.

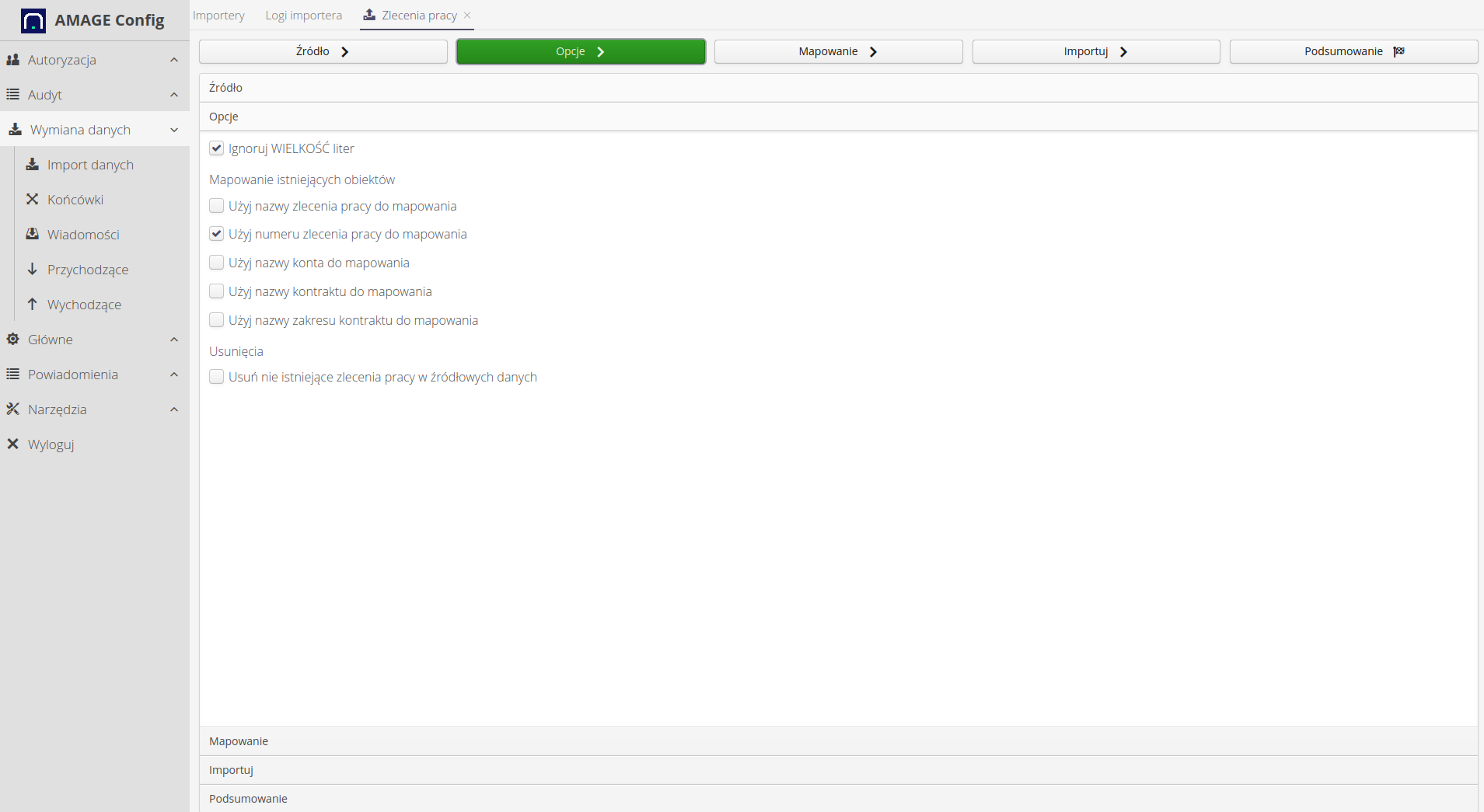

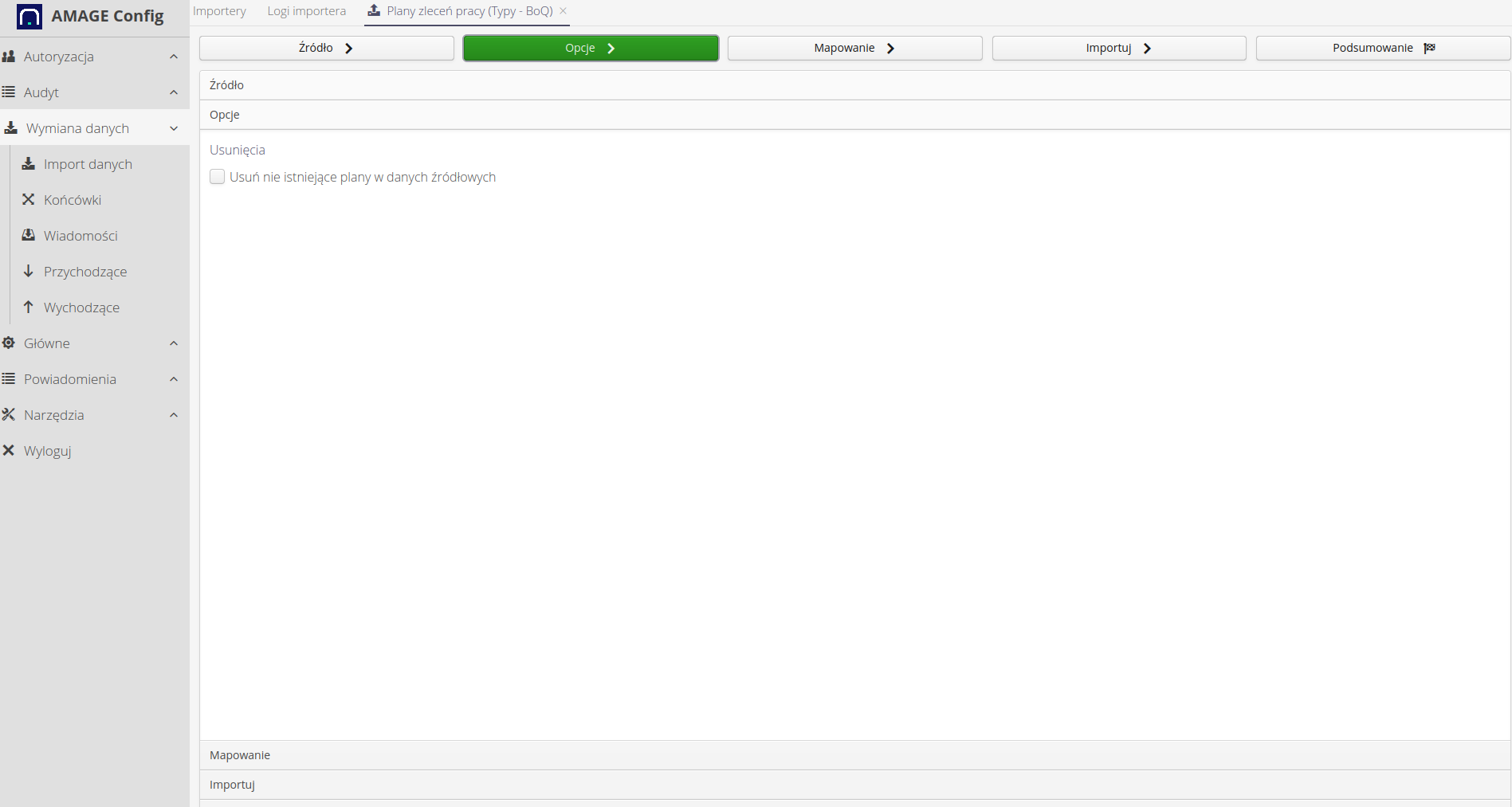

We define general importer options.

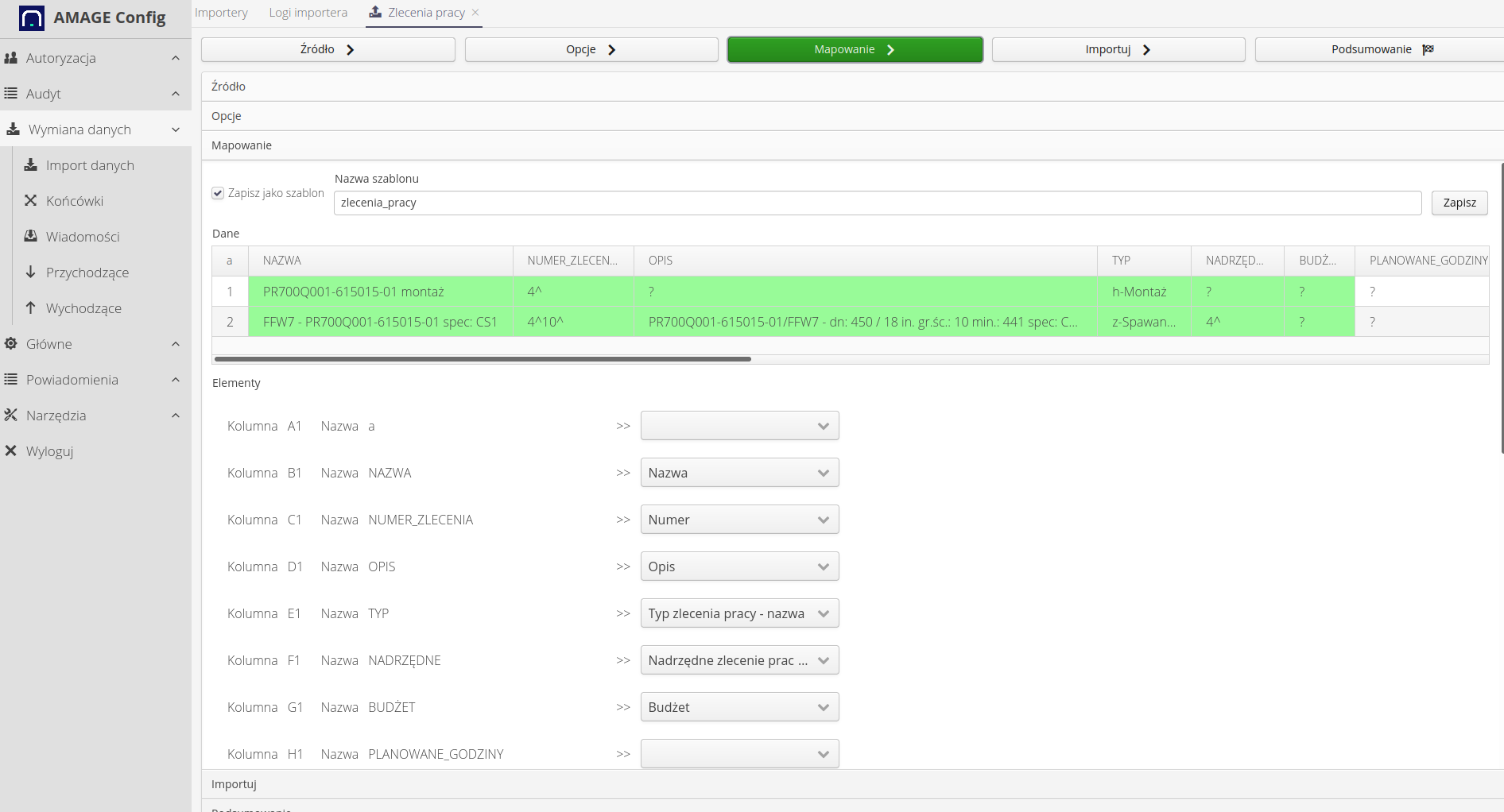

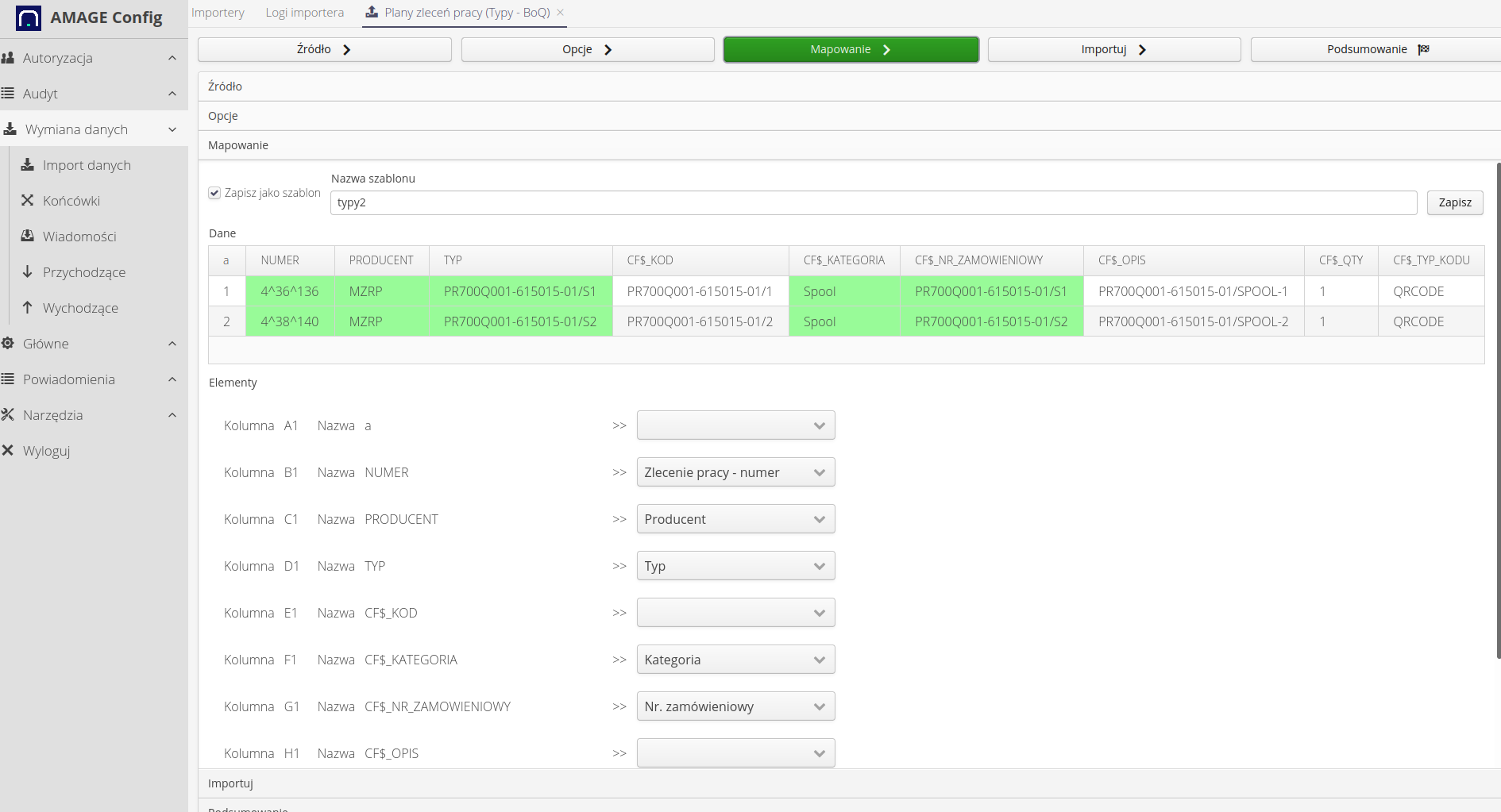

We map the fields in the file and determine their meaning.

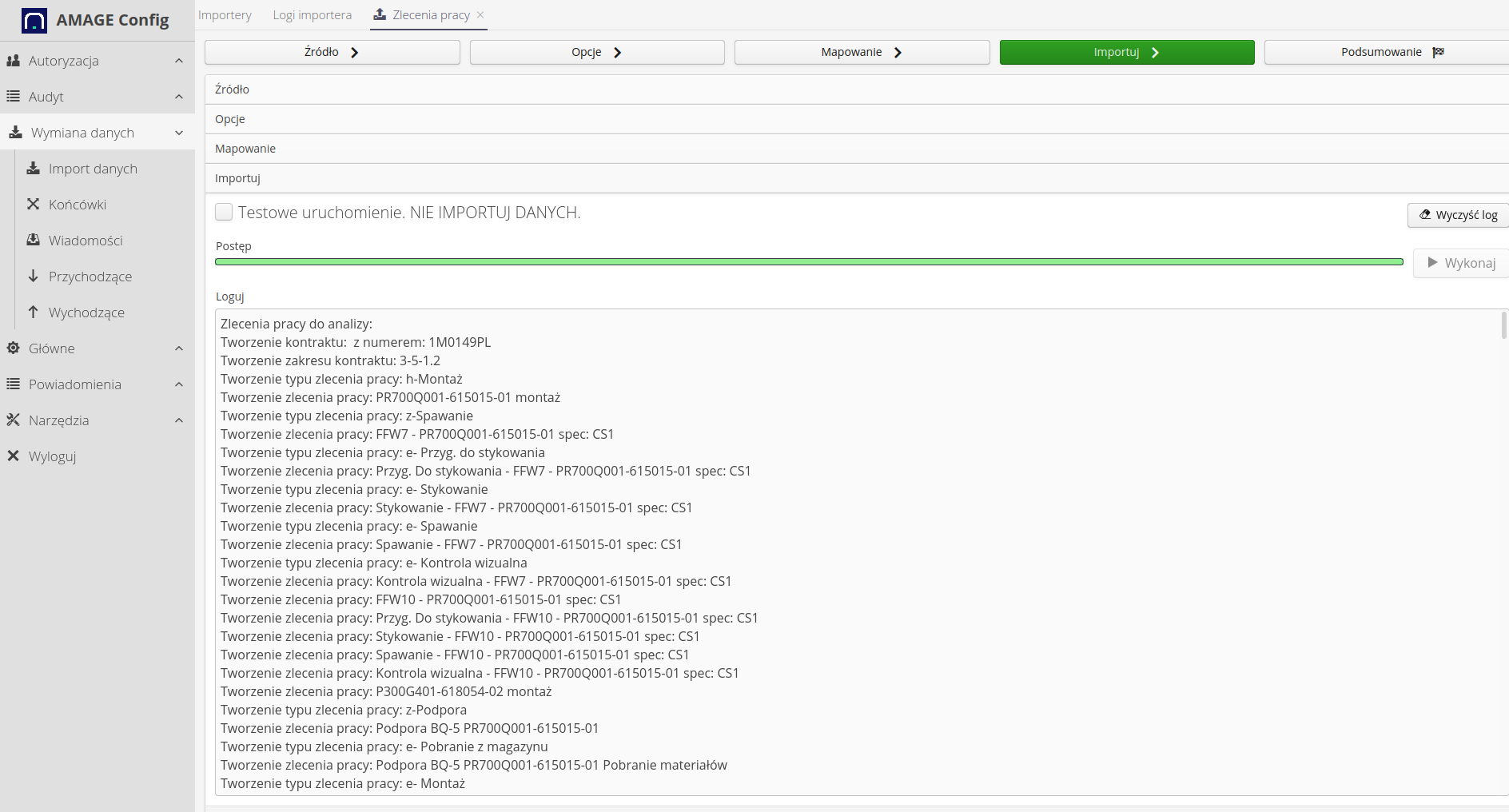

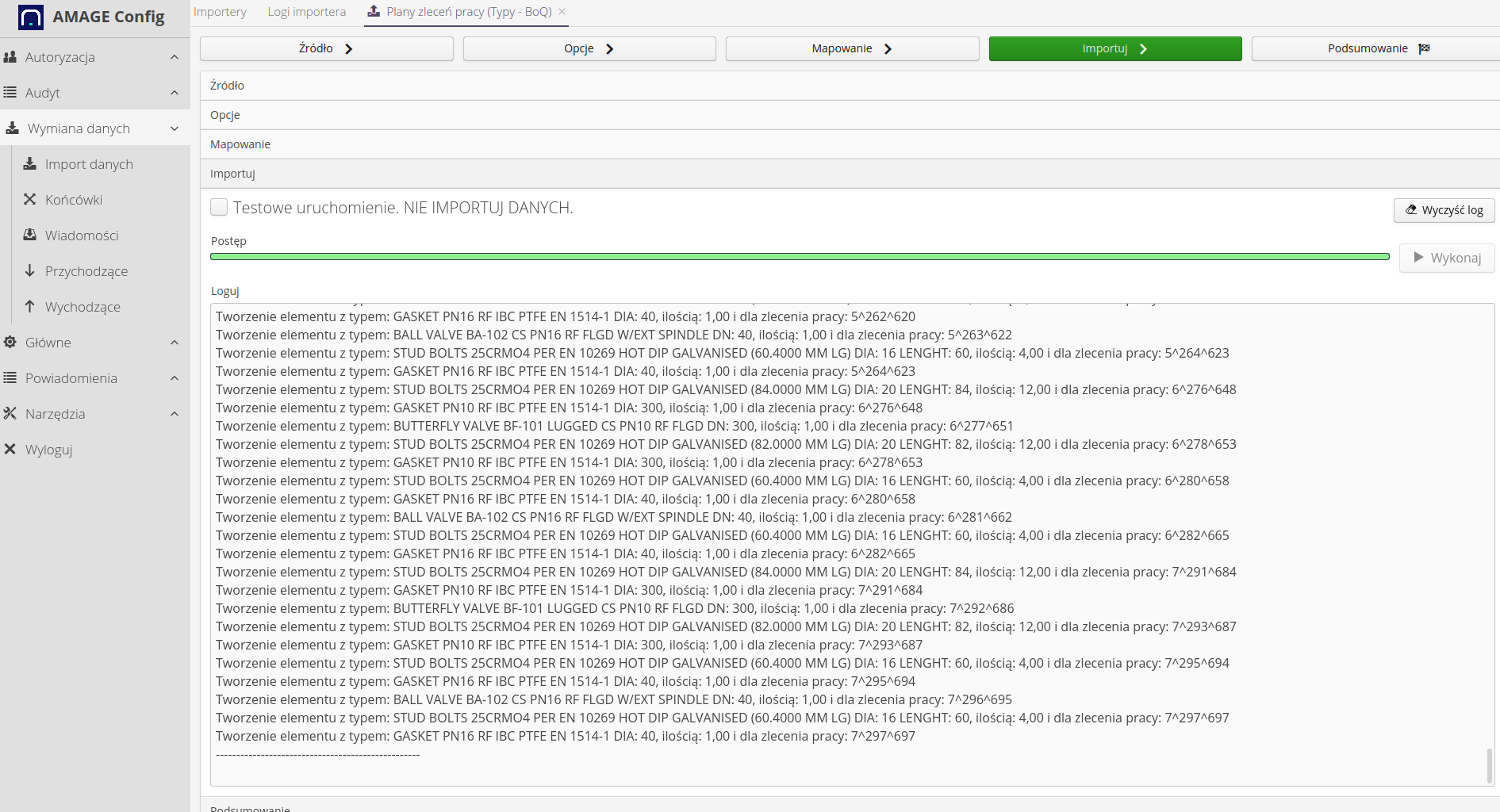

We import into the system.

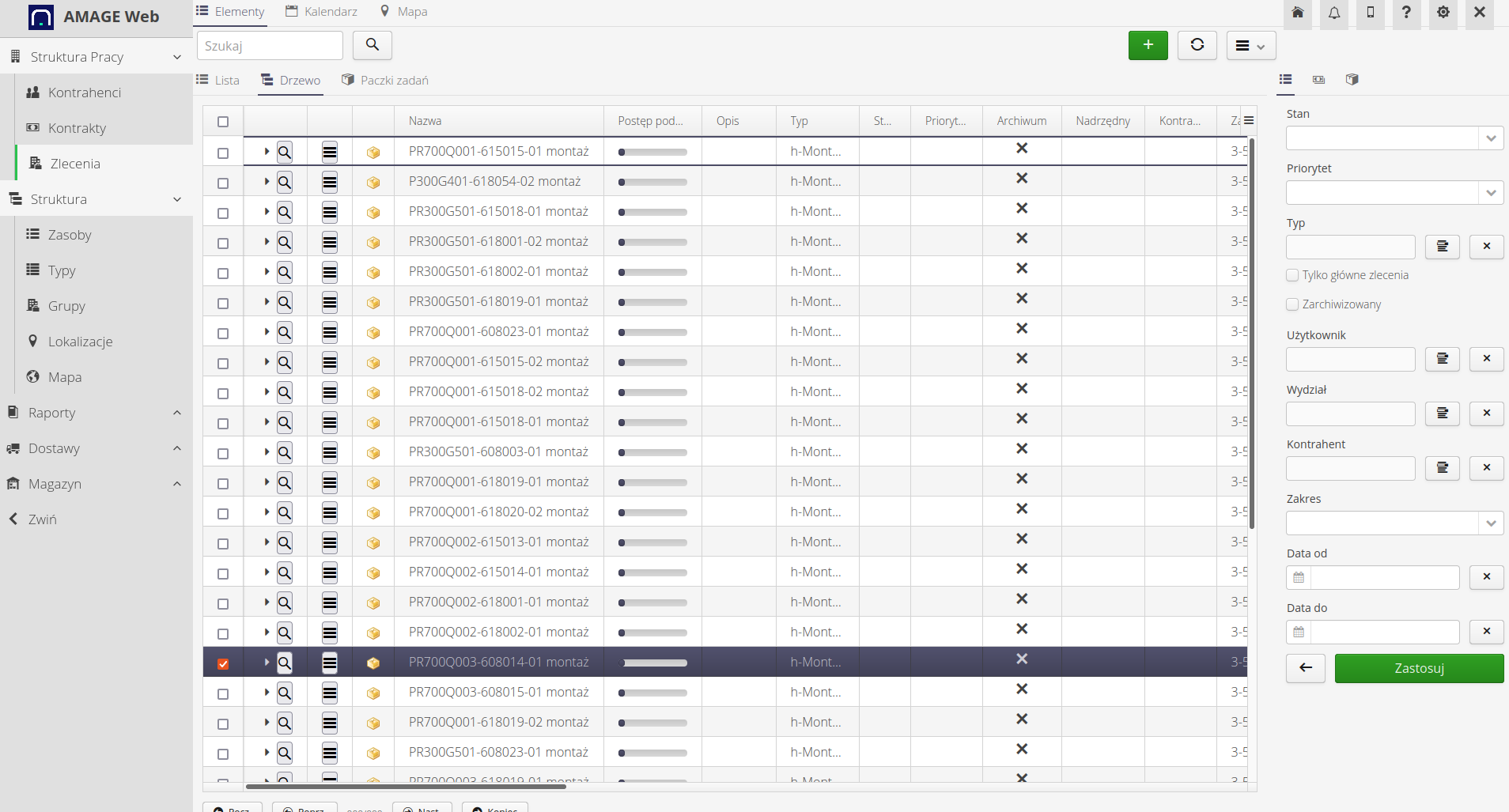

As a result, we receive a list of tasks to be performed along with subtasks. The scope of fields to be imported is wide (import of schedule, task assignment, etc.).

To associate tasks with previously imported element types and resources, we need to perform two additional imports.

Work orders - list of material plans

One file contains a link between the assortment (types of elements) and work orders, along with specifying the amount of a given material necessary to complete/order.

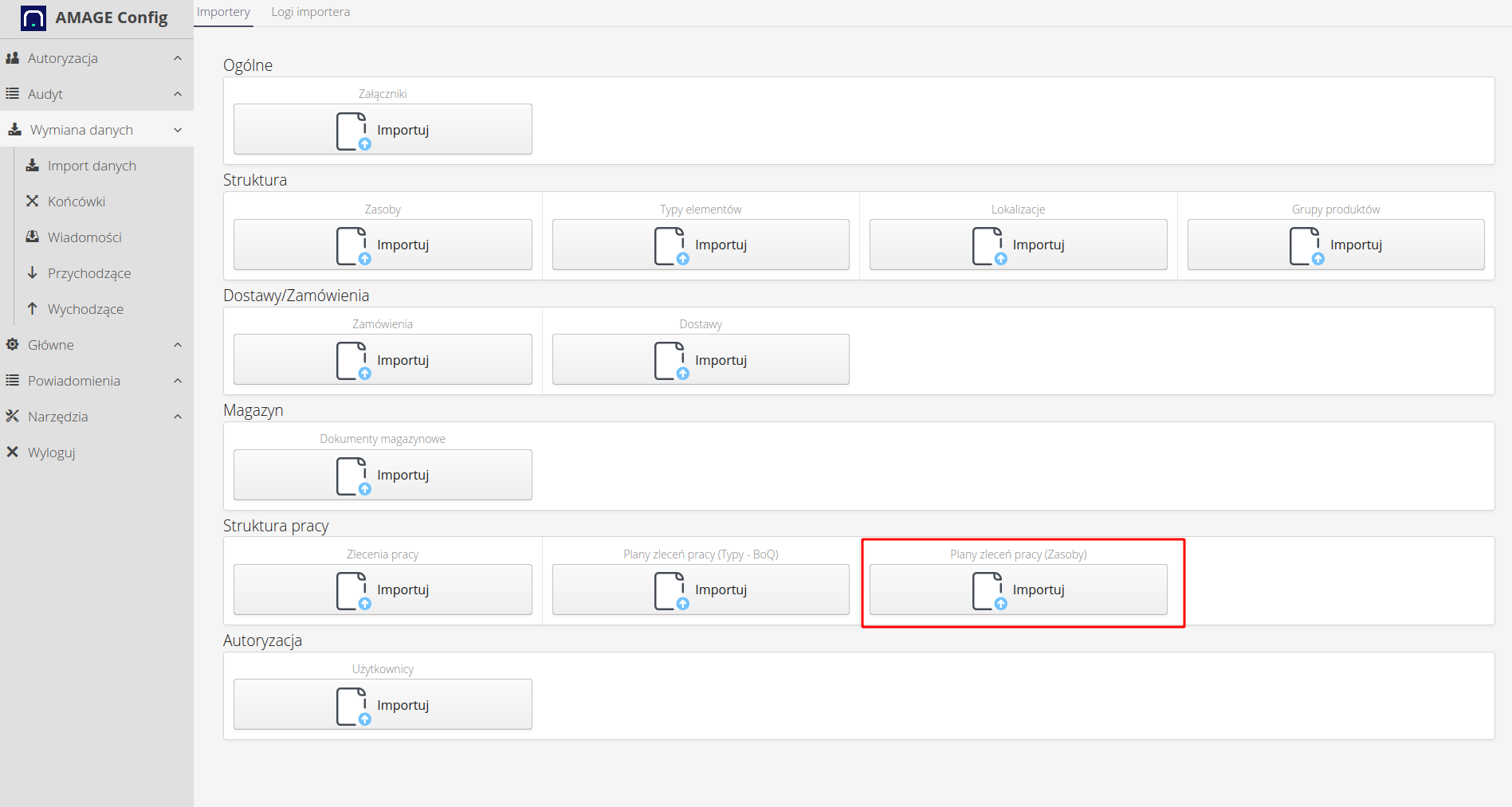

We select the importer from the list.

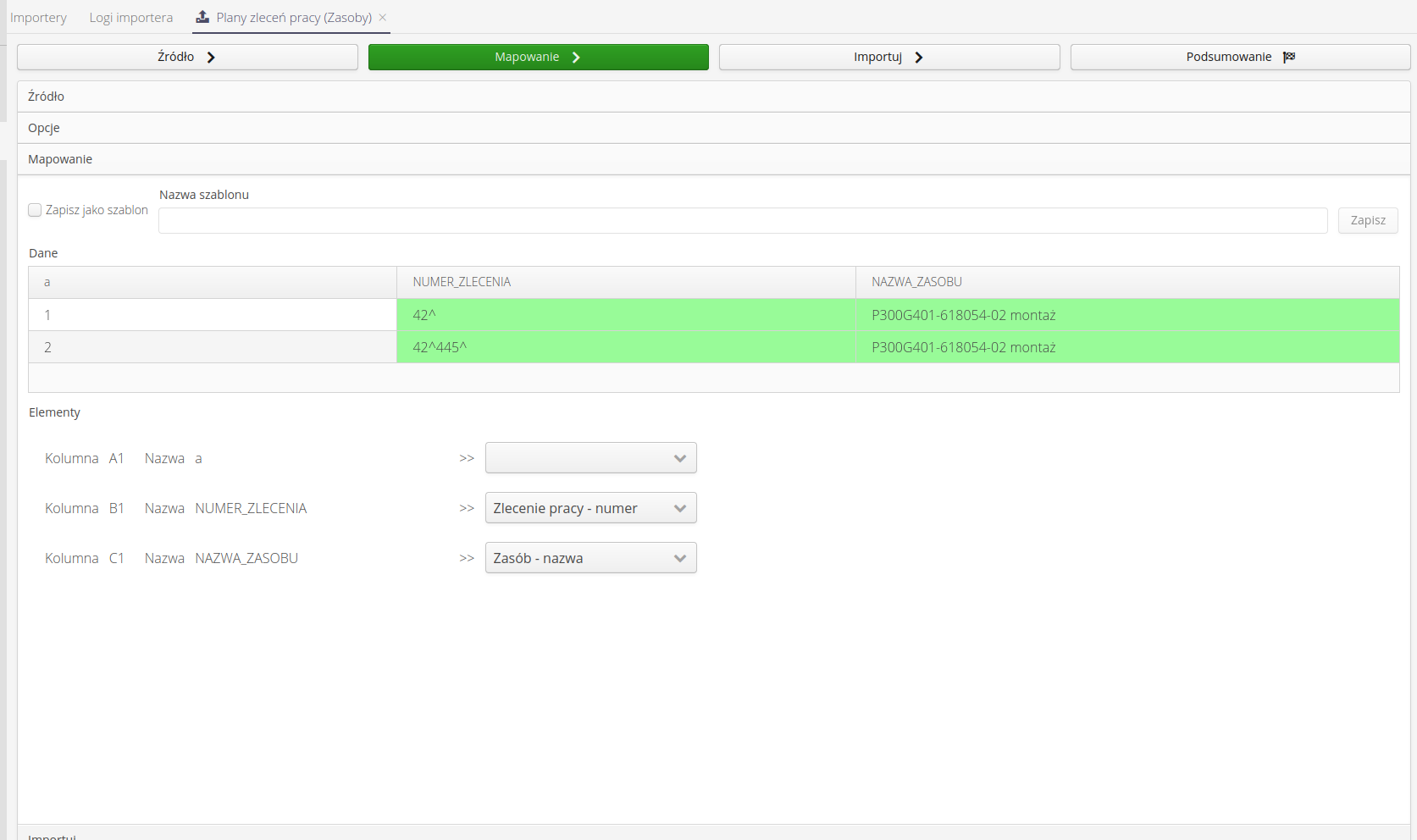

We choose the field mapping in the imported sheet and their meaning. The main task here is to indicate the relationship between types and work orders.

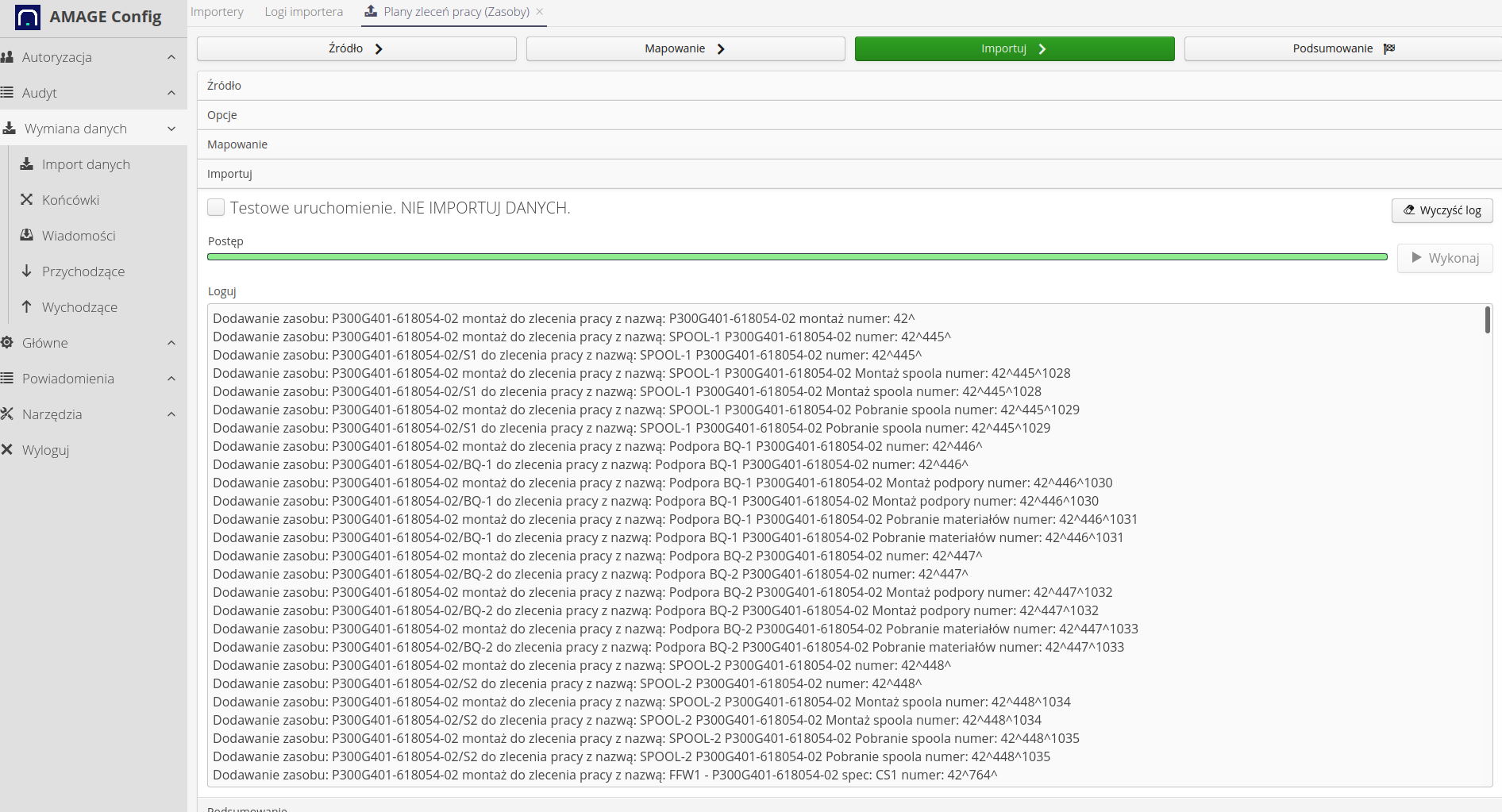

We import data into the system.

As a result, we receive a list of materials in the work order and a material plan. From here we will be able to order them or generate an order to the warehouse for delivery.

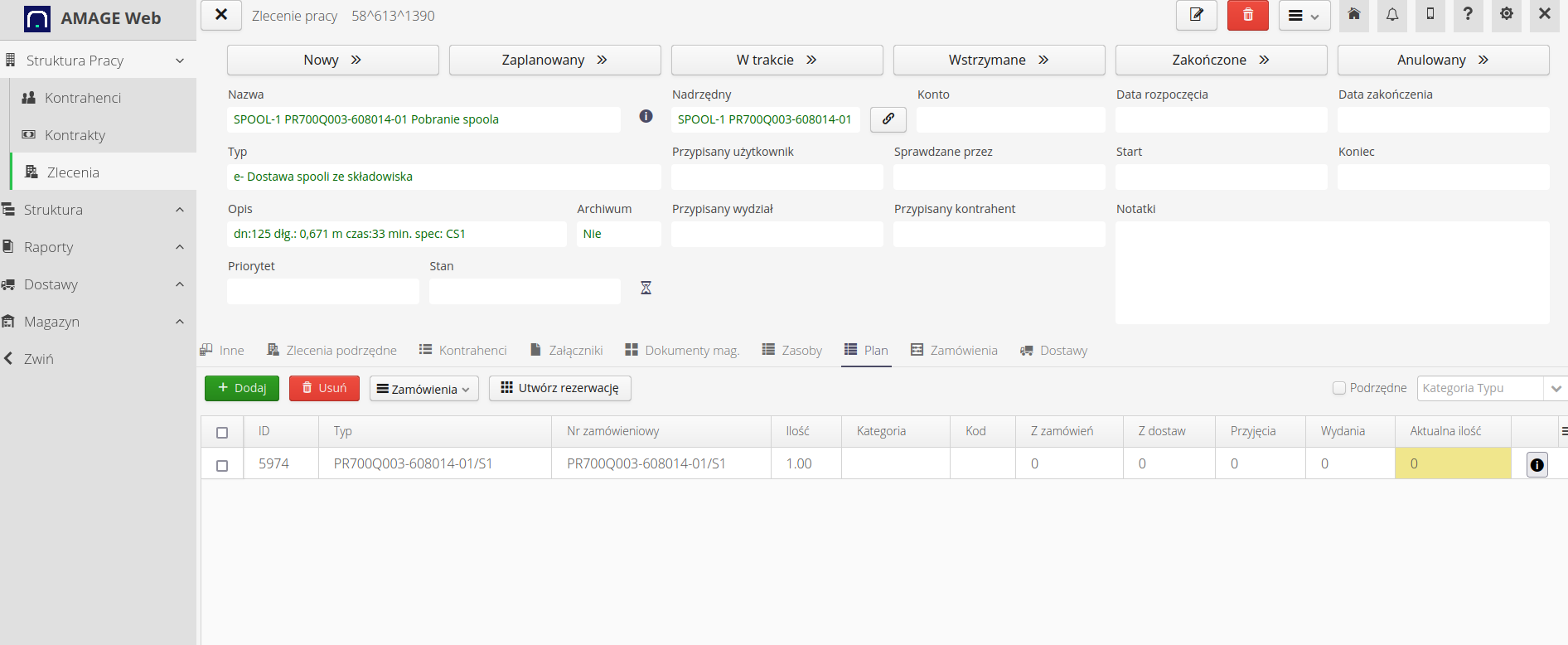

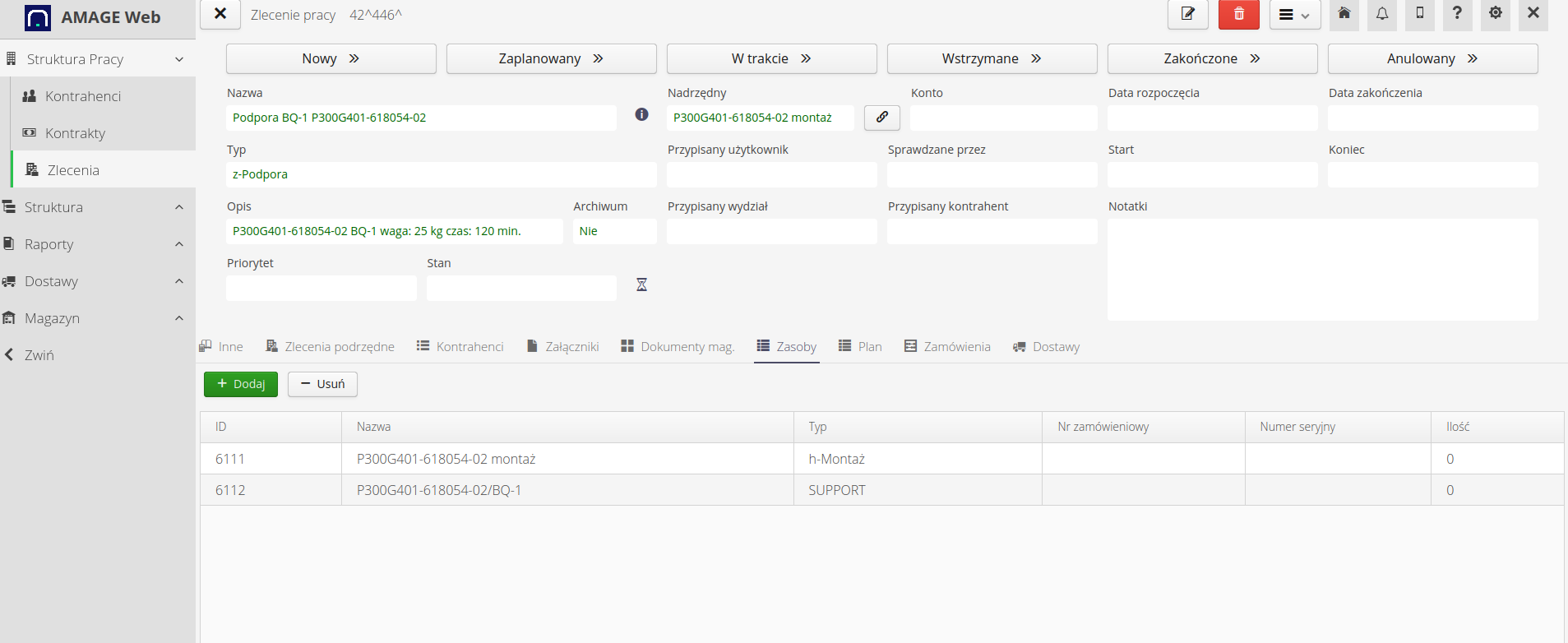

Work orders - related resources

The second link is to link resources to work orders. We carry out similar activities.

As a result of these operations, we receive information about the resources associated with the work order. Based on this data, it will be possible to conduct further automation or quickly navigate between the task to be performed and the data of the resource (parameters, documentation) that needs to be performed.

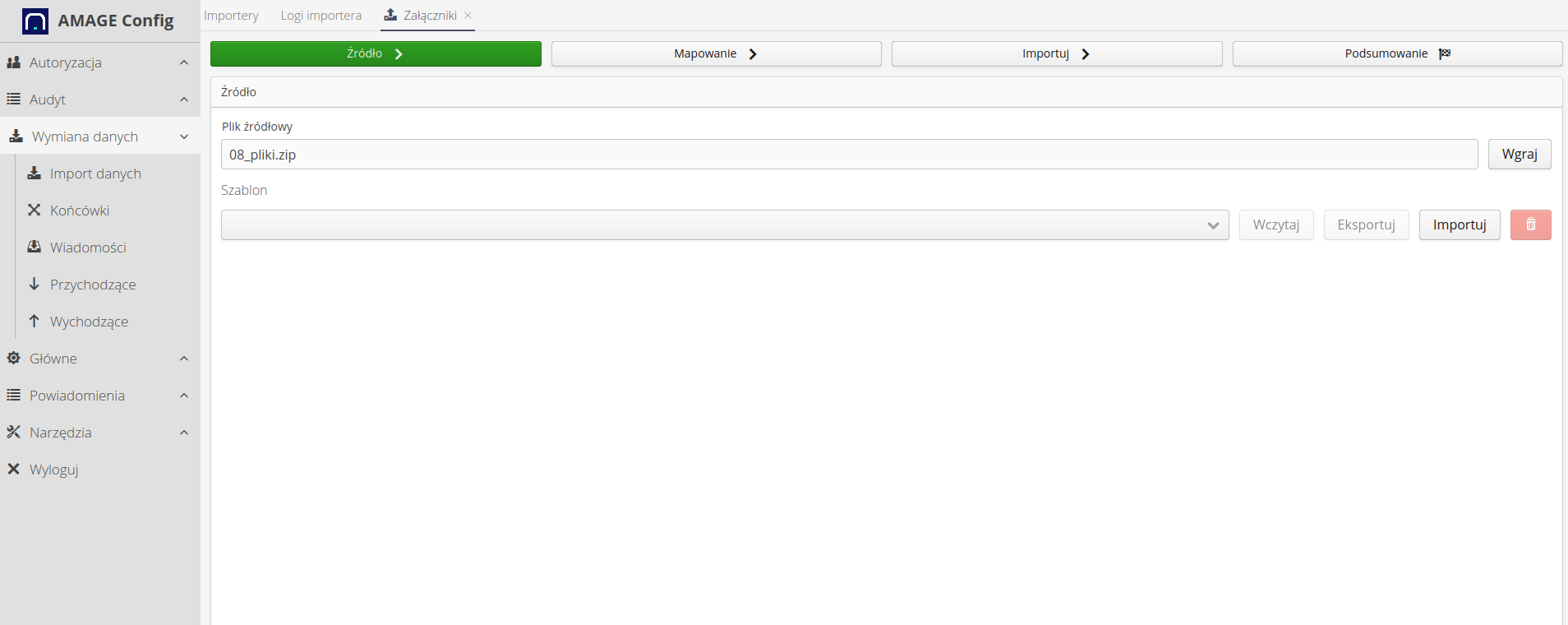

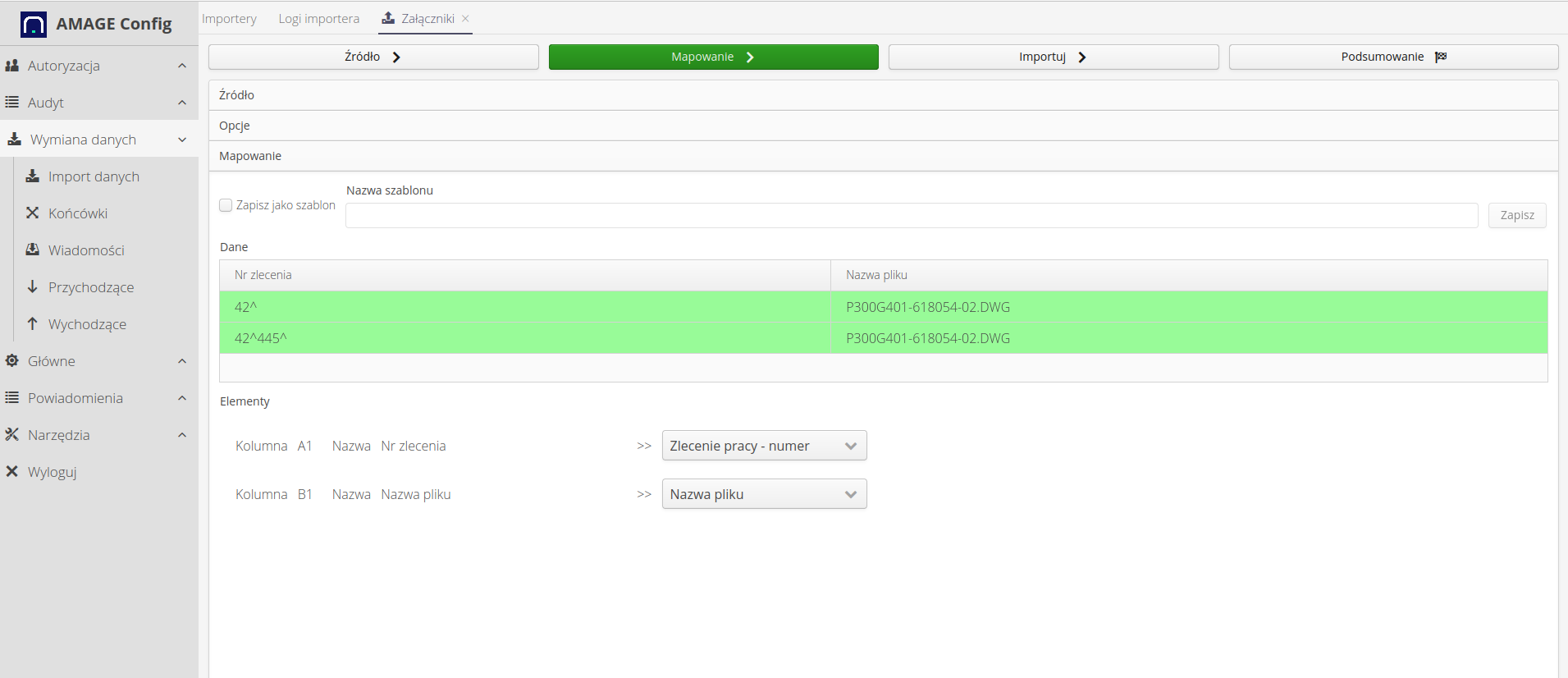

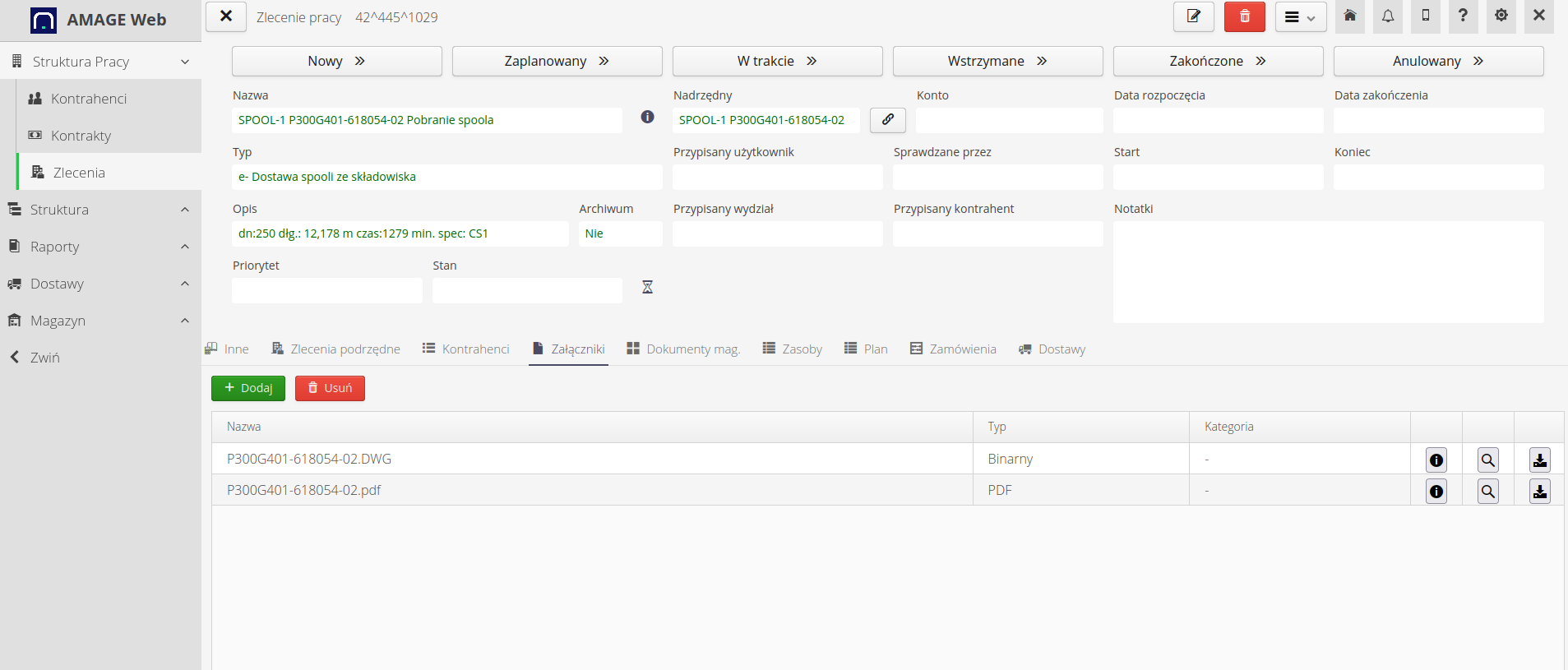

Attachments for work orders/resources

In the process we describe, additional documentation is often created, which is very useful during the work performed. The attachment importer allows this. Unlike previous importers, it works on a ZIP archive containing files and an XLS sheet that contains information about which resources/work orders a given document should be attached to.

To create such an importer, we create:

-

zip archive with all files (they may be in subdirectories) and one xls file called import.xls(x)

-

the import.xlsx file contains information about the file path and name, as well as information about the resource or work order to which we are linking the file.

We load such an archive into the system.

| you should pay attention to the size of such an archive. It is recommended not to exceed 100MB per archive file. If you need to import a larger number of files, divide them into several imports. |

We define the mapping between the file and the resource or other object handled by this importer.

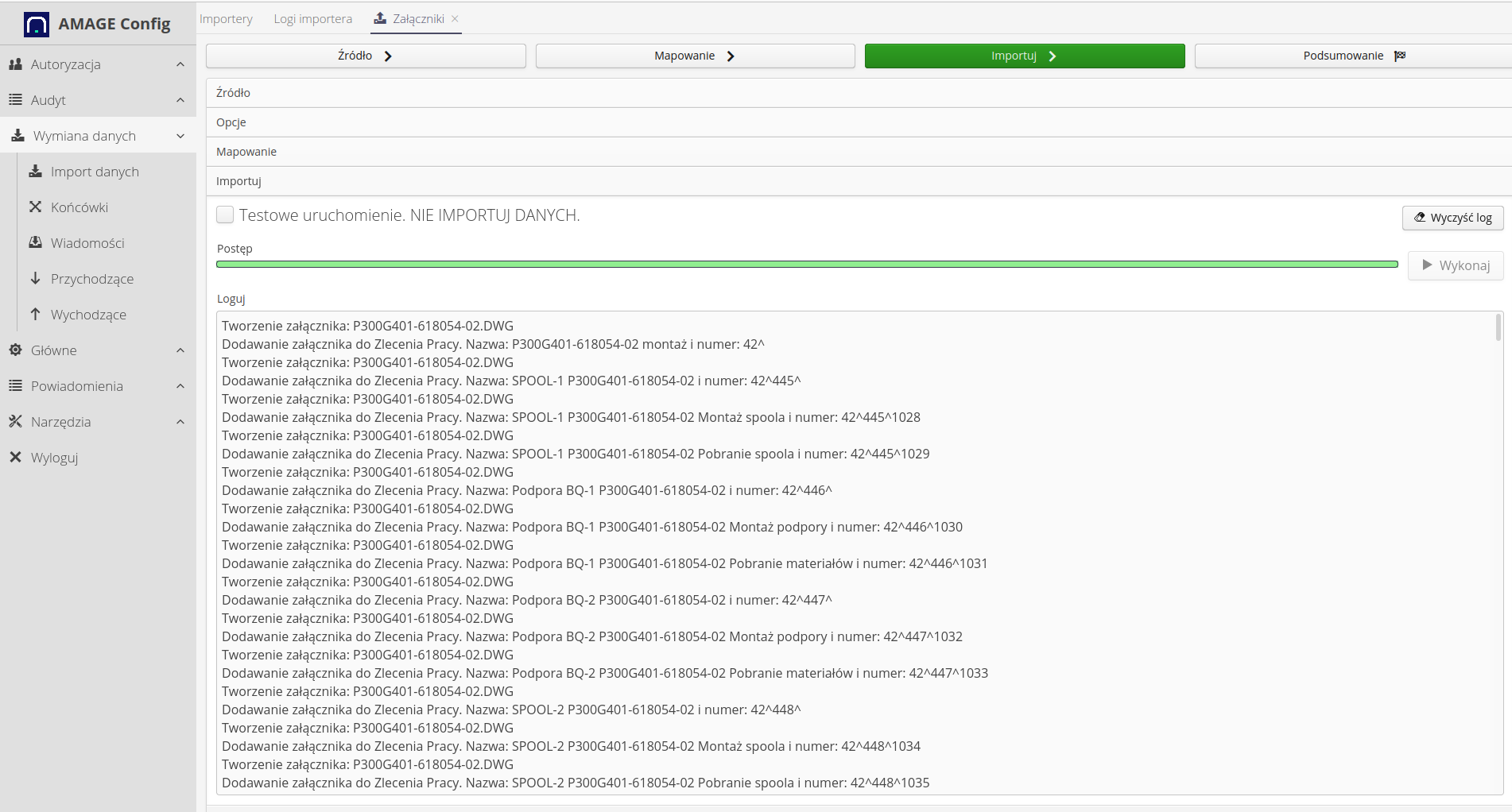

We import.

As a result, attachments appear in specific resources and can be viewed and downloaded.

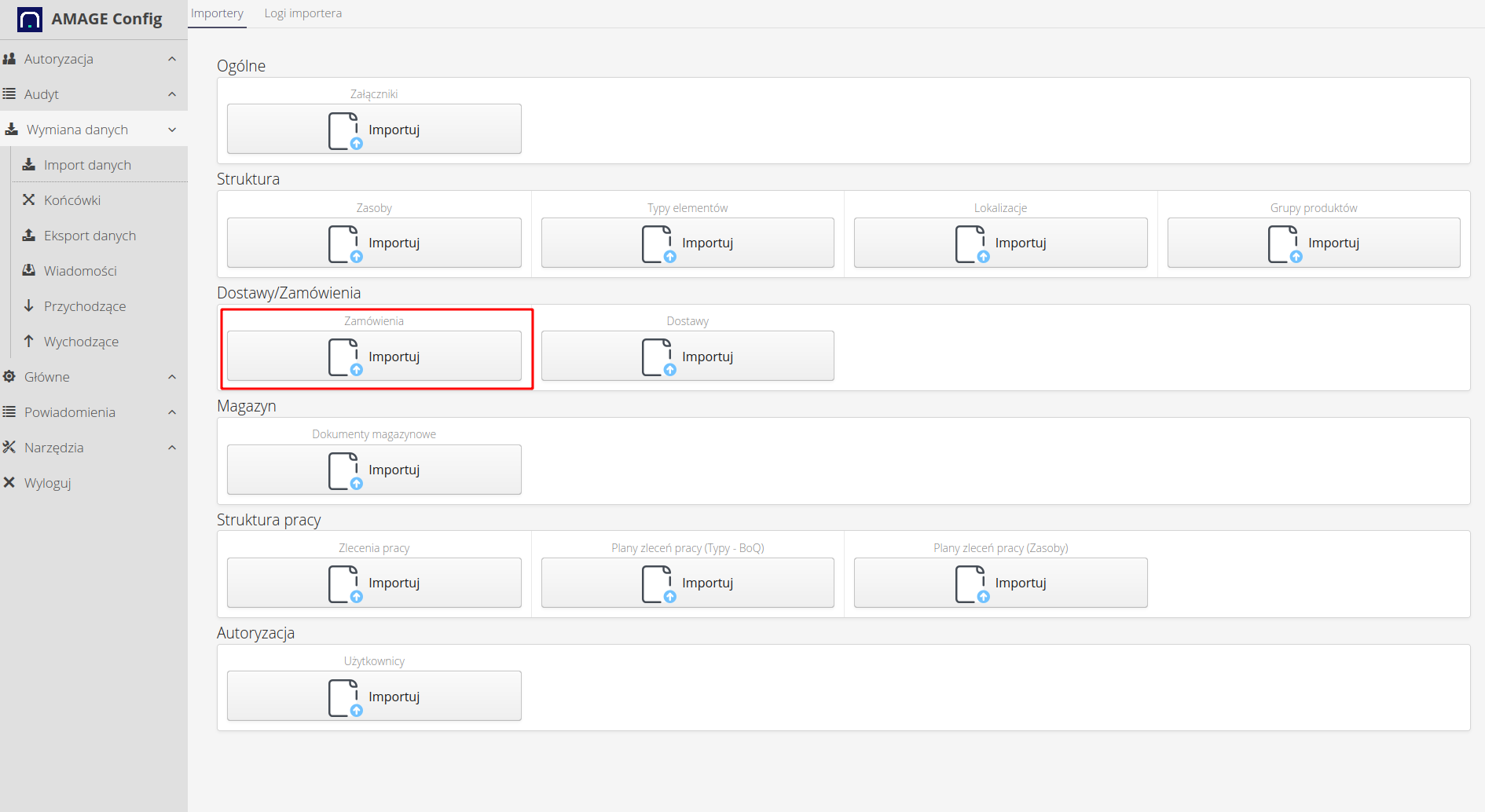

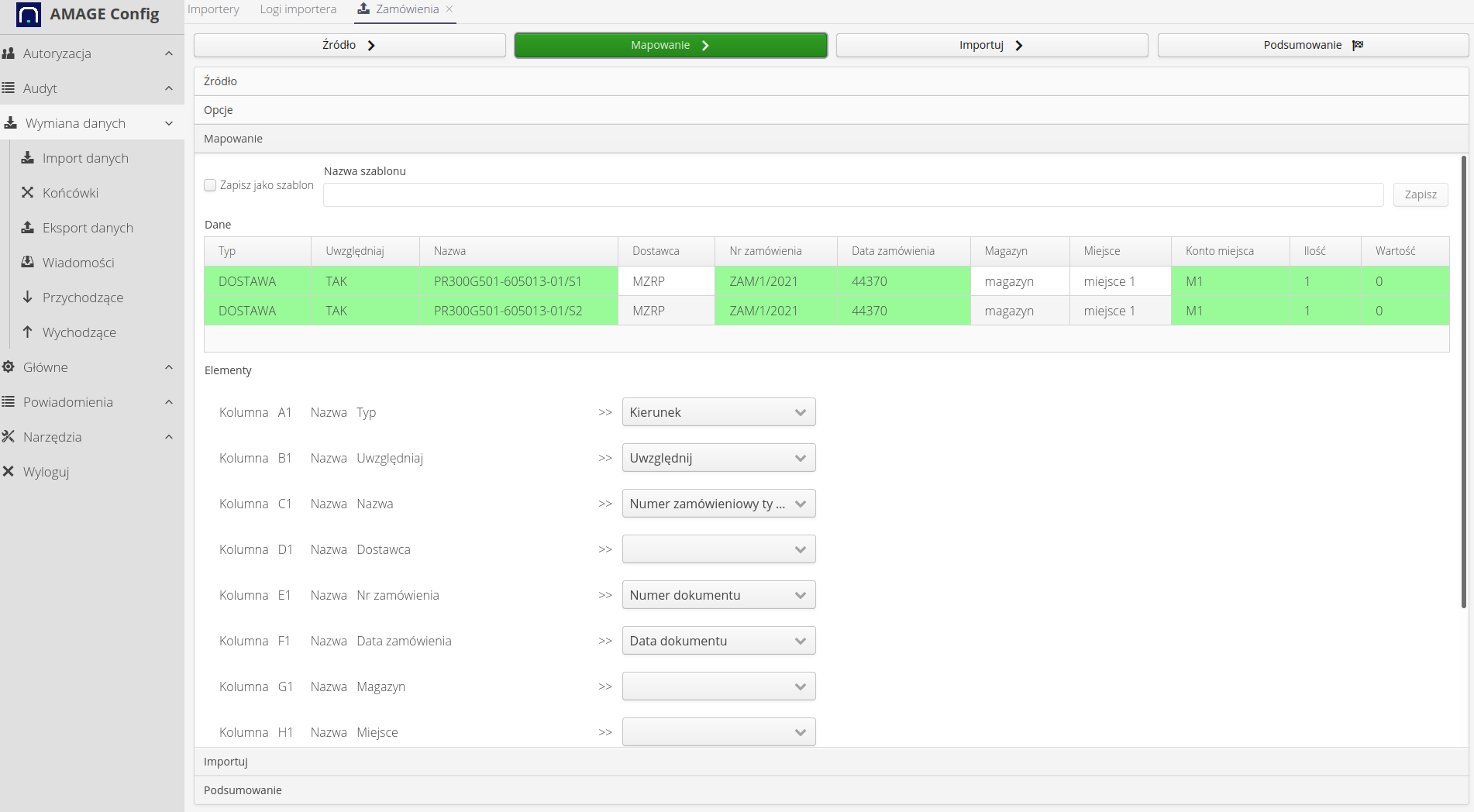

Orders

The final step in this tutorial is to import order/delivery data. We use an order import mechanism.

We select the order importer.

We define the mapping of individual fields and perform the import.

The end result is imported delivery orders with material details.

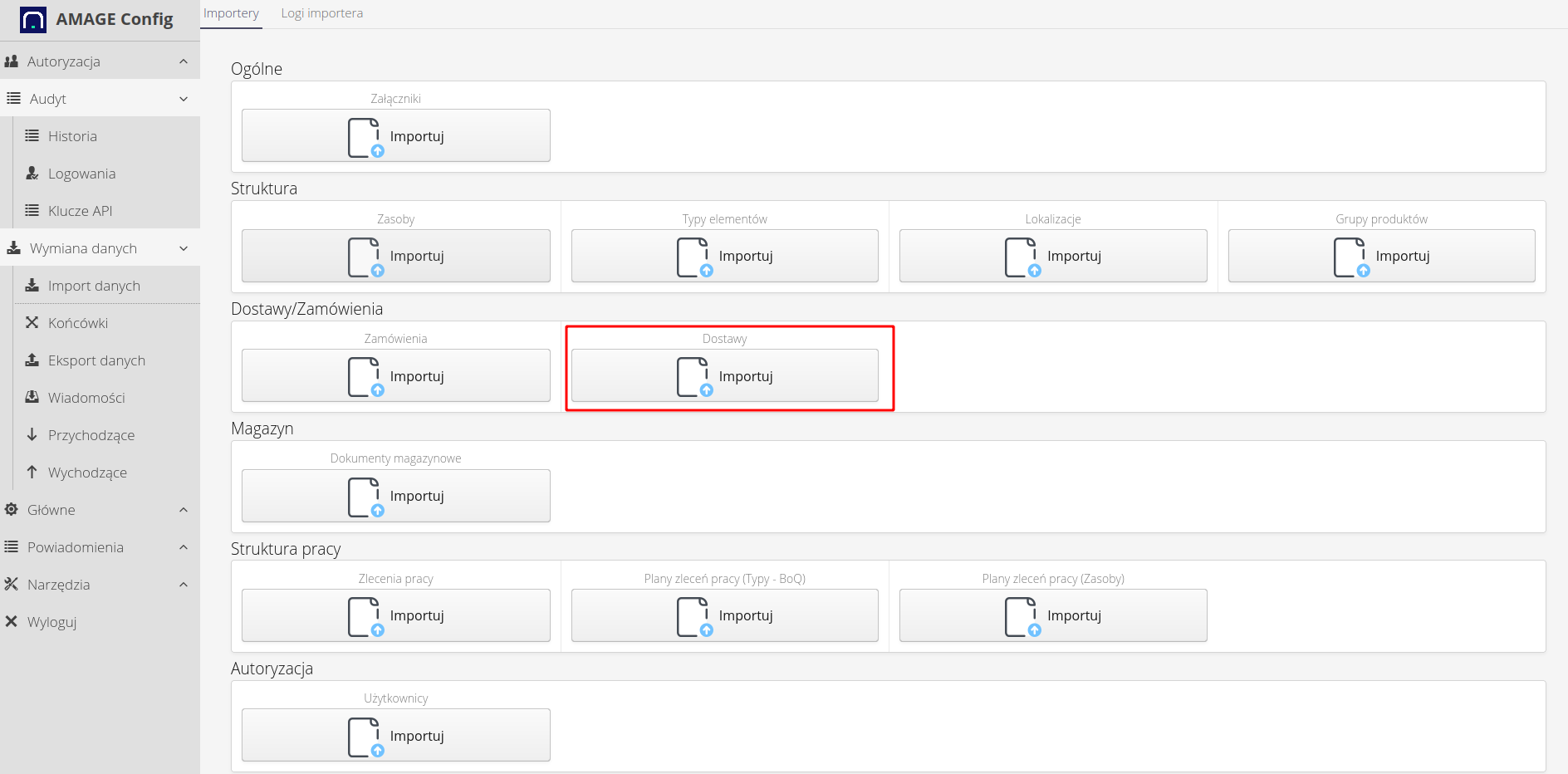

Deliveries

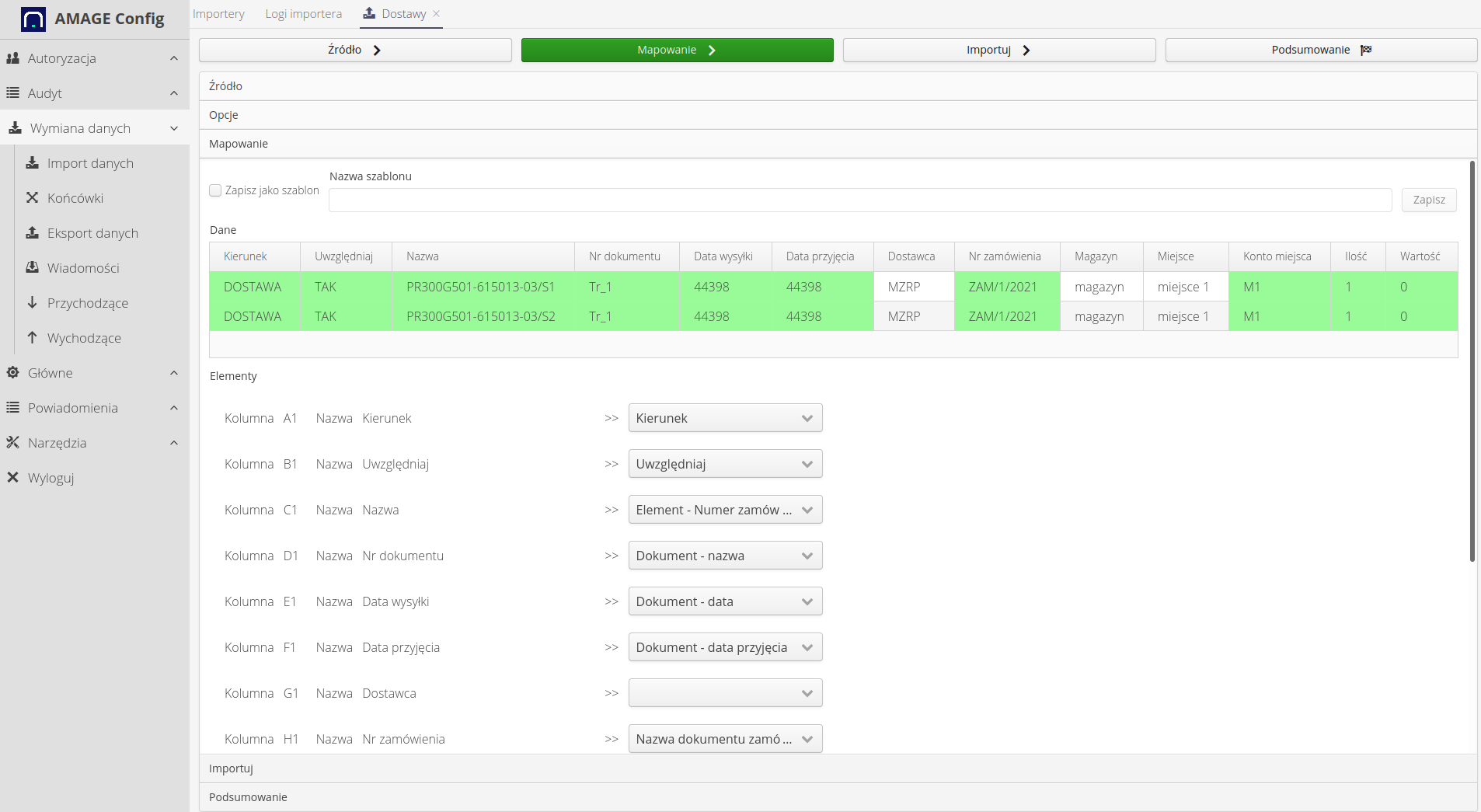

We import supplies. Identical to other operations. We choose a supply importer.

We define the fields and their meaning and perform the import.

Deliveries appear in the system. Using the delivery module, we can verify their completeness, create complaints or transfer the material to warehouses.

Summary

In this way, we imported a significant range of data from the areas of orders, deliveries, data structure and work orders. We divided the imports into individual stages and used the available importer functions to adapt to the existing XLS/CSV data files. We can now use this data in the system.

Further automation may also be the next steps. While defining these imports, we saved individual templates. Now we can enable integration, e.g. via email, and set the system so that when an XLS file arrives with delivery, it will be automatically downloaded to the system and imported in relation to the template for a given supplier. The possibilities are endless :)

| The Howto is based on system version 1.17.0.2 (03.2022) and presents features that may not be available in your system. Ask AMAGE about making this functionality available. |

| Due to ongoing development of the system, some screens or configuration files may look slightly different, but will still retain the full functionality described here. This does not affect the core functionality described in this document. |