Electrical supervision - drum management

Introduction

The document describes an example of import, management and supervision of cable drums used for cable works. The goal is to make it possible to manage the available cable drums. After the drums have been delivered and their capacity (declared cable length of a given type) has been determined, the system enables supervision of the drums themselves (their condition, location, length declared by warehousemen) as well as supervision of the wear and tear of the cables used to route the sections during the execution of these works. The used drum information is recorded for each cable section. Reports allow you to generate information about the use of drums and cable allocation.

Description of the solution

| The system is based on the cable work supervision already imported and activated in the system. It is described in detail in another document. This document is partly based on the data established in this regard. |

Descriptively, the implementation of the required functionality may look like this:

-

preparation of an Excel sheet with data of drums available during implementation at the construction site and planned for delivery. Usually there is such a list. The most important elements of such a sheet are the drum type (the type of cable on it), the drum ID (can be a sequential number) and the original length of the drum at the time of delivery. There may be additional parameters in the sheet (reel weight, turning radius, inner diameter). They can be helpful in determining, for example, a conveyor for transport or other calculations.

-

we import a list of drums into the system using a standard resource importer. We place these drums in a separate product group.

-

we define and run drum supervision to track drum condition and location.

-

we generate and print identifiers for drums. We mark the drums with these identifiers.

-

we modify (if it does not already have) the supervision of cable works, so that the used drum is also recorded at the time of laying the cables.

In addition, for the purpose of access to analytics, we follow the steps:

-

in the main configuration, we set the drum parameters that will be used to generate reports and dashboards. The system must know in which drum parameter the data necessary for the automatic generation of reports is stored.

-

we generate reports and analytics

| If the delivery module is enabled, it is possible to automatically enter new drums in accordance with the supplier’s declarations. The delivery in this case must define the identification of drums (serial number). The automatic serialization and supervision initialization mechanism is described in another tutorial. |

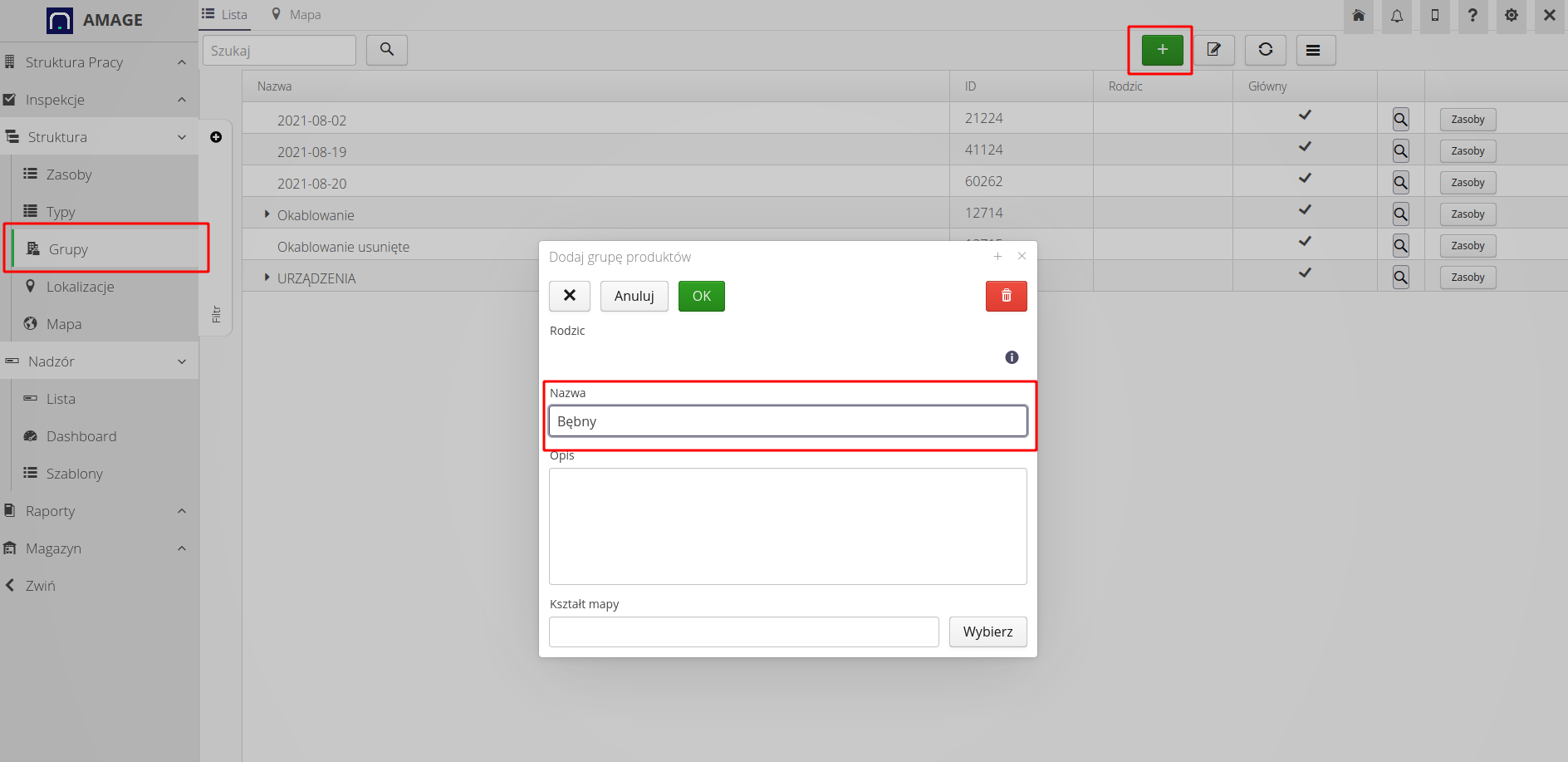

Initial data

We define the group to which we will import the drums. It will contain drums imported from an Excel file. This is to enter the drum data into a specific group. Additional subgroups or a main group can be defined in the Excel worksheet. It is up to the data importer to decide whether he wants to additionally divide the imported drums into internal groups.

Drum list import

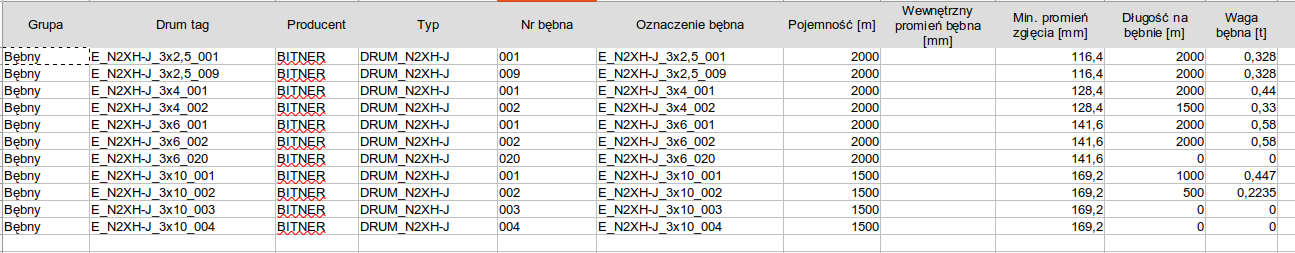

The Excel file contains information about individual drums. These data can be entered already in the system (parameters), but they can be imported from external systems. We use the general spreadsheet for the definition.

| After importing this data, it is possible to enter new drums manually using prepared drum types (parameters). Import only automates a few operations that can also be done manually. |

The content of the file is data on:

-

group to which the drums will be imported

-

manufacturer, drum type (cable type)

-

drum name (unique)

-

drum parameters - ordered length, etc.

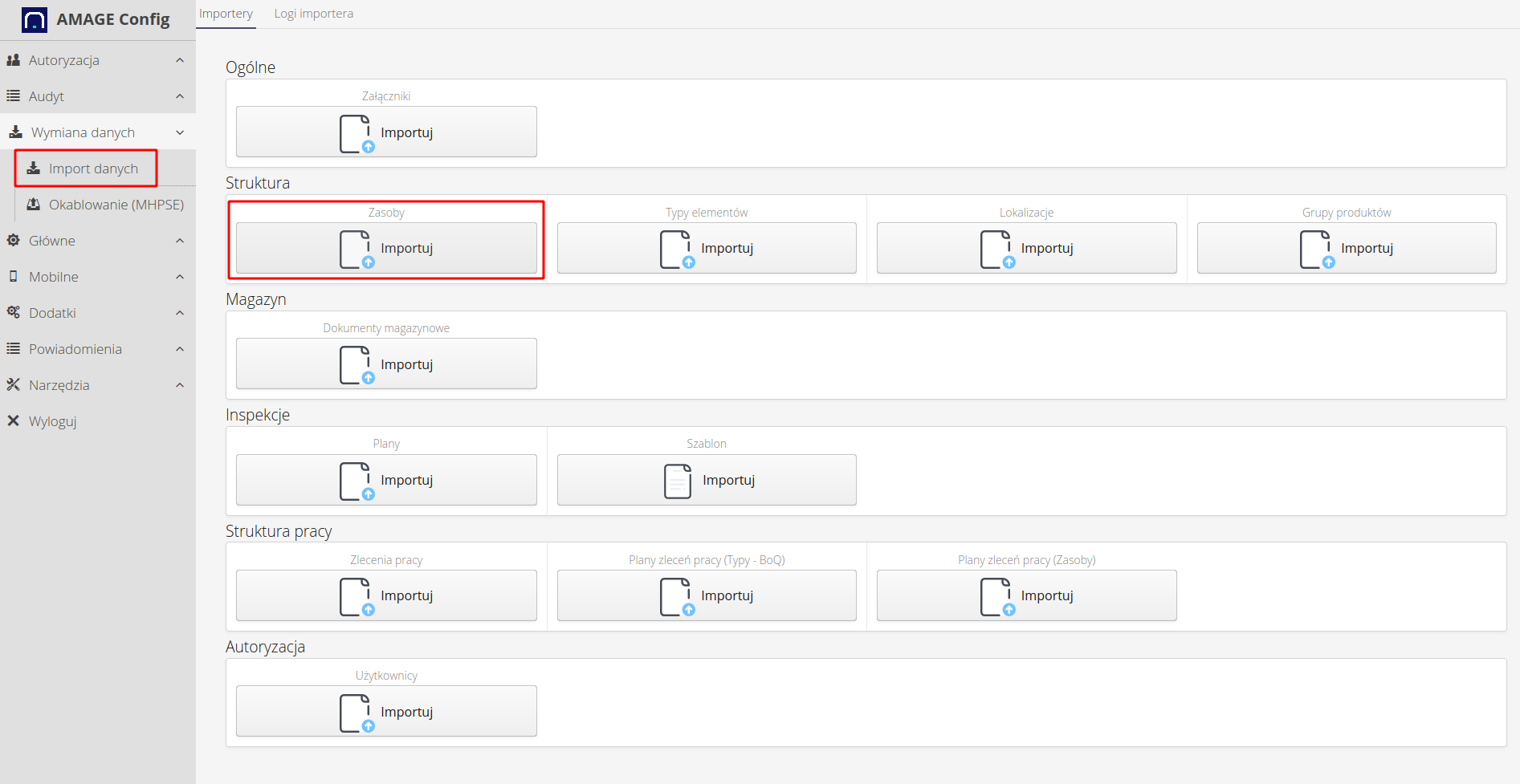

To import data, go to the configuration section and select imports and resource import.

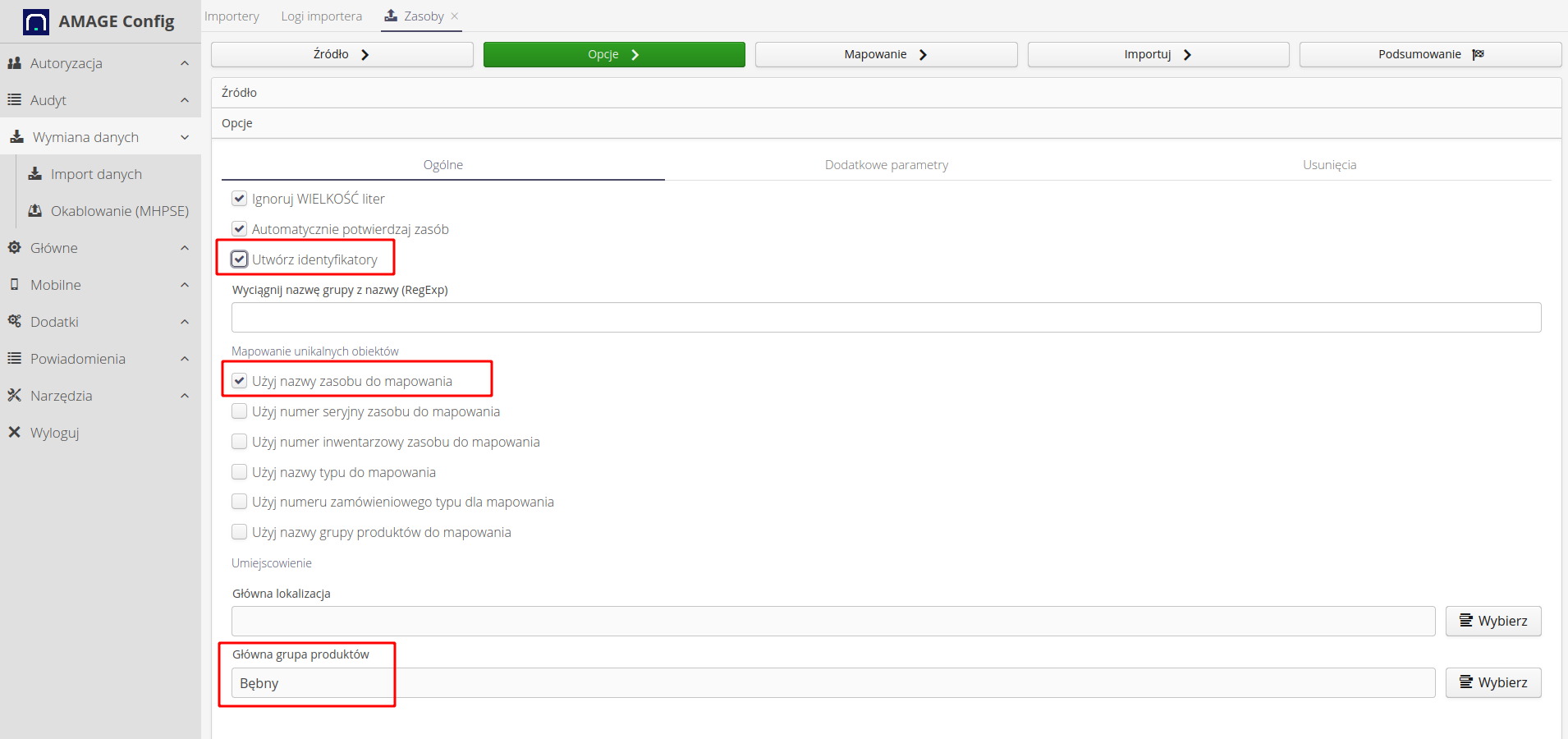

In the options, we choose mapping by element name and group. We also automatically add identifiers during import. This will allow you to generate and assign identifiers and print them later (it can also be done later).

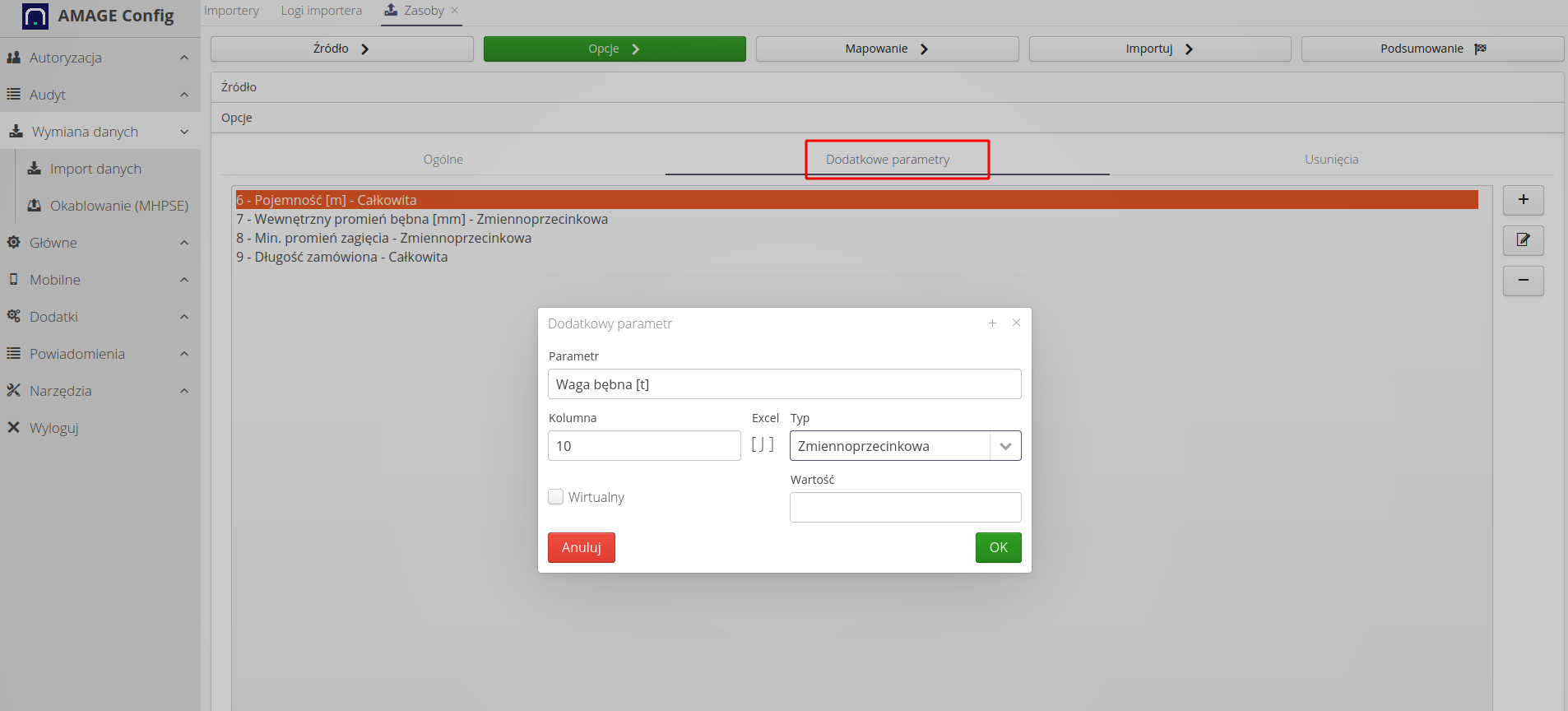

In the case of drums, we define new additional parameters for them. The import sheet contains additional information resulting from the design process, i.e. total drum capacity (in [m]), drum radius, minimum bend radius and ordered length. We can store any number of additional parameters for a given type in the system. In this case, part of the data will be informative and part will be used in the reporting process (ordered lengths).

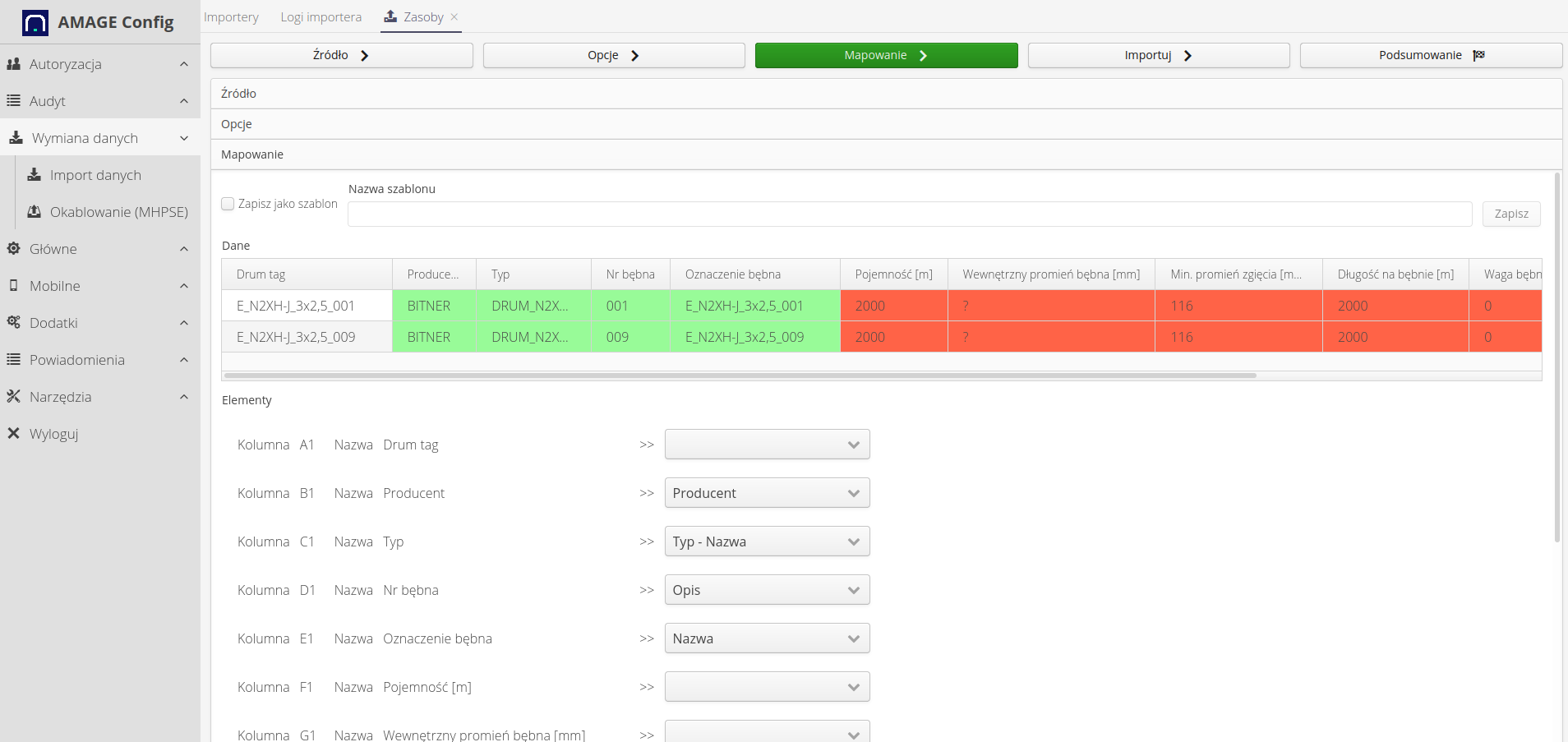

In addition, we map the main fields that define basic parameters such as name, type, manufacturer and mark the import to the group with the given name 'Drums'. This will automatically create such a group in the system and enter all drums inside that group.

| It’s good practice to categorize drum types right away. It will be possible to use it in the supervision definition in the next steps. Of course, you can assign a type to a category after import in the system. |

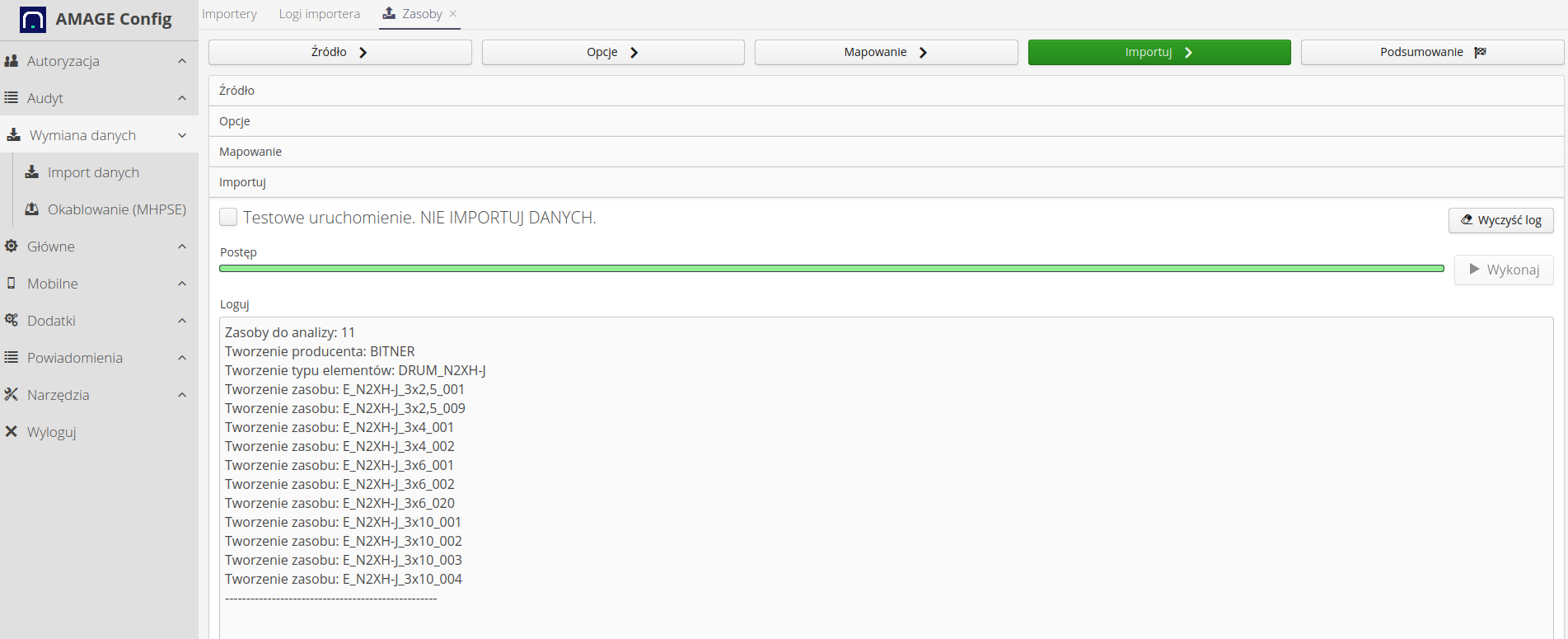

We import data with saving to the database.

After this step, the basic drum data is imported into the system.

The system allows you to re-import drums with automatic detection of existing drums. We marked the mapping by name during the configuration, i.e. if during the import the system finds a resource with the same name in a given main group, i.e. Drums (!), the data will be checked and updated against what is in the Excel sheet. If there is no such drum, it will be imported as a new one.

|

Supervision initialization

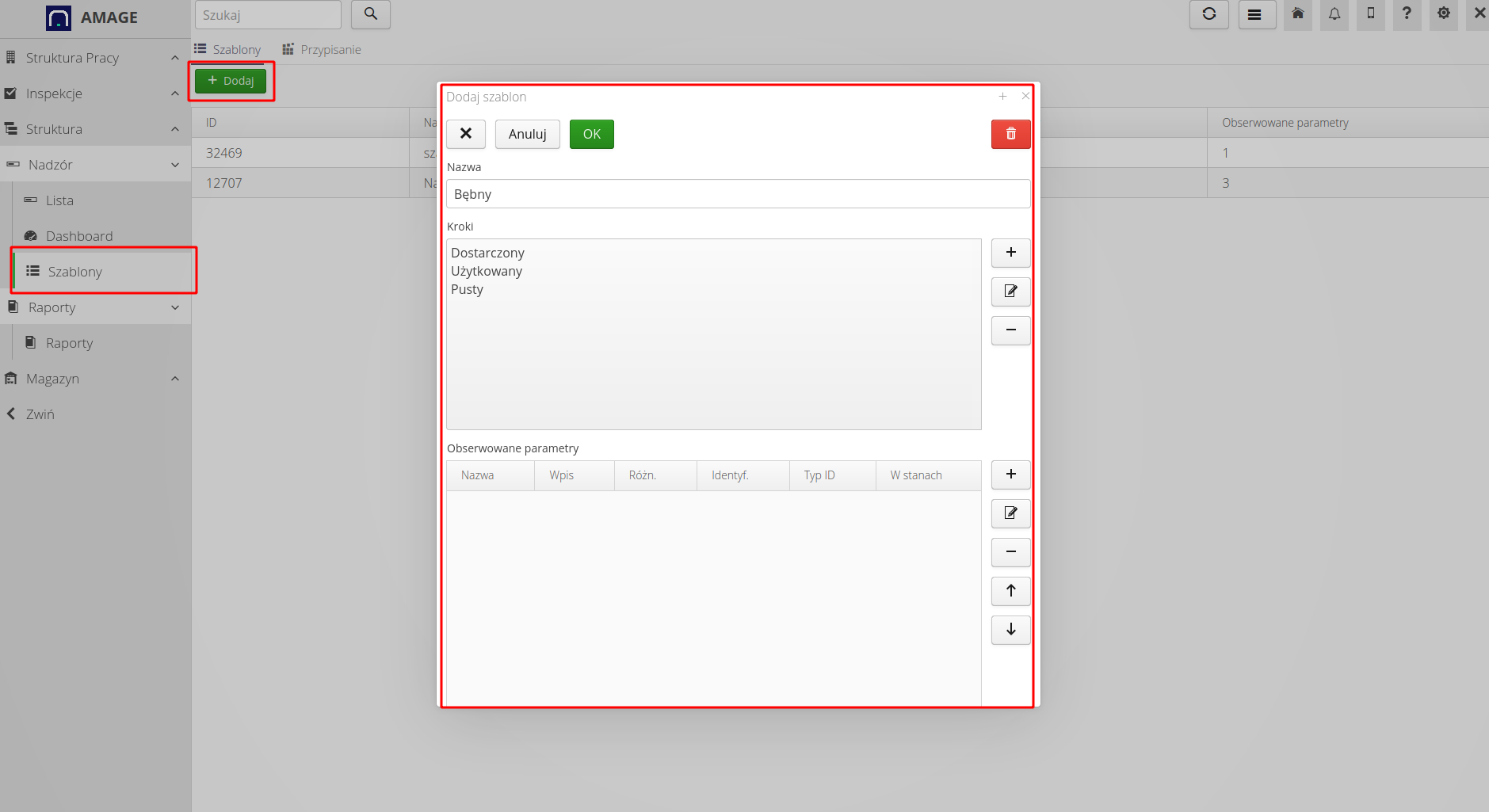

For imported drums, we create supervision to be able to track their path and exploitation. We define appropriate states in the system. For basic monitoring, it is enough to define states without monitoring additional parameters.

| Users may additionally want to monitor an additional parameter, e.g. the current length of the cable on the drum resulting from the warehouseman’s report. Where drums are stored in temporary storage at night, this may help to check stocks when receiving/dispensing to such storage. In this case, we add a monitored parameter to such states, e.g. "current length on the drum". |

We associate all drum types with the given supervision and initiate supervision after selecting all drum types.

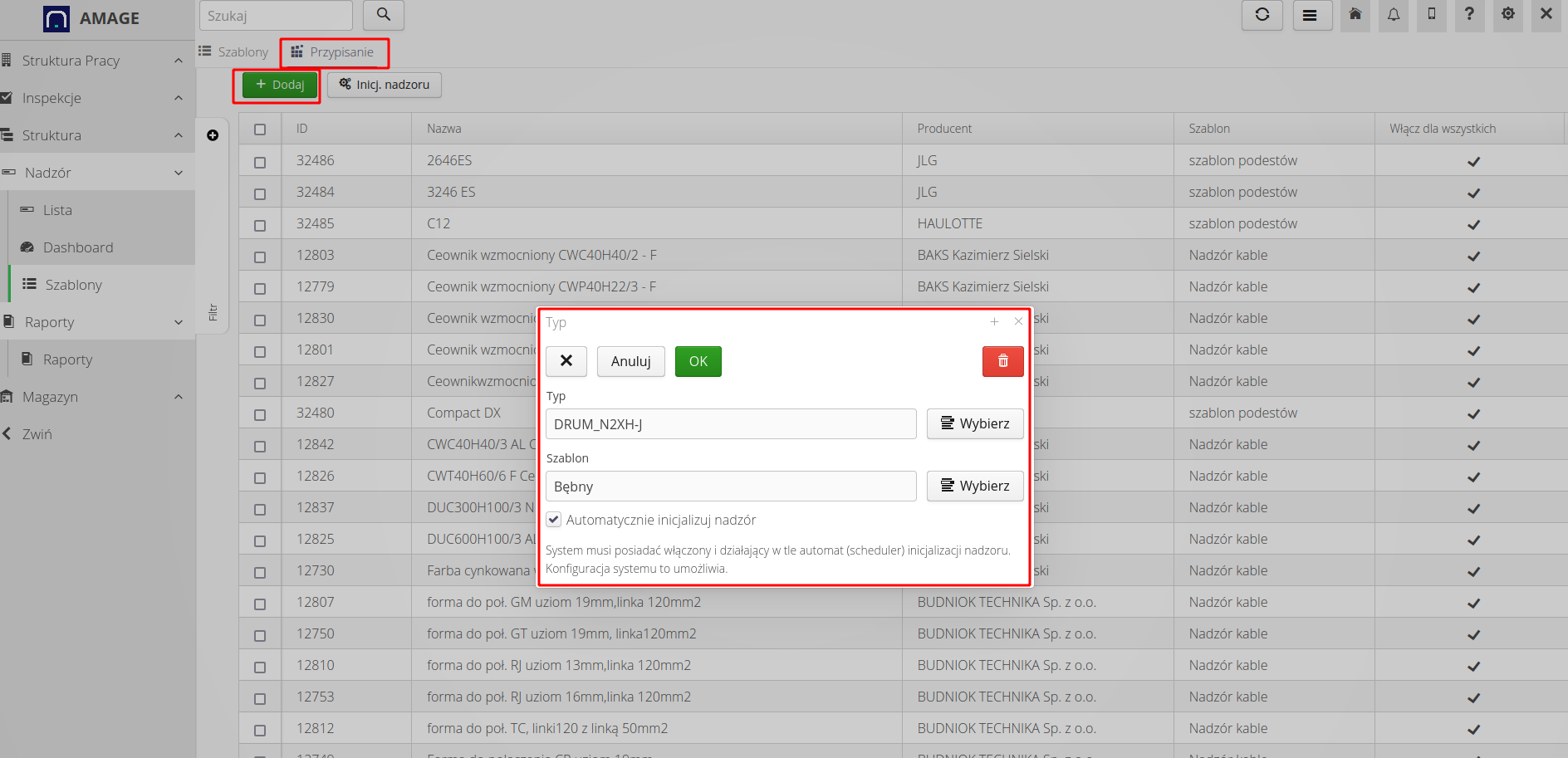

Alternatively, when we have specific categories for drum types, we can define supervision in a simplified way. We only select a category of types and assign a supervision template to it. This will allow for faster initialization of supervision for all types of assortment data, e.g. drums, cables, etc. This option is available in the supervision view.

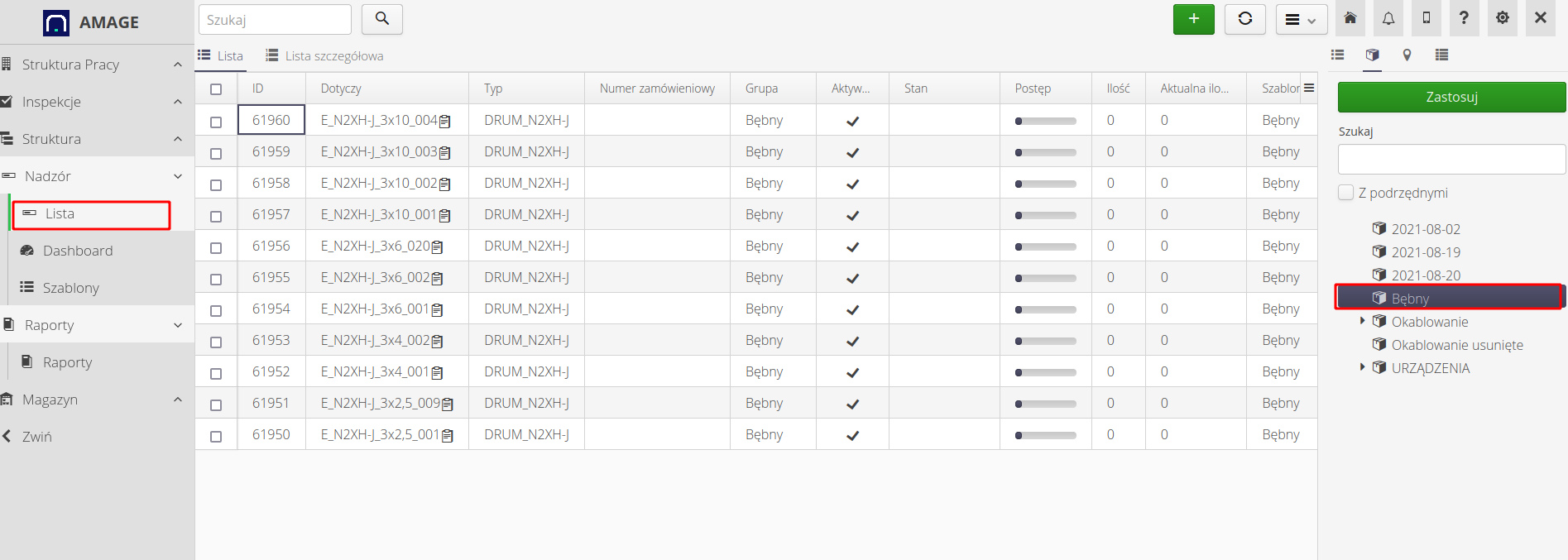

Result: We get initialized supervision for drums. You can record the status of individual drums.

Configure properties for cable/reel supervision

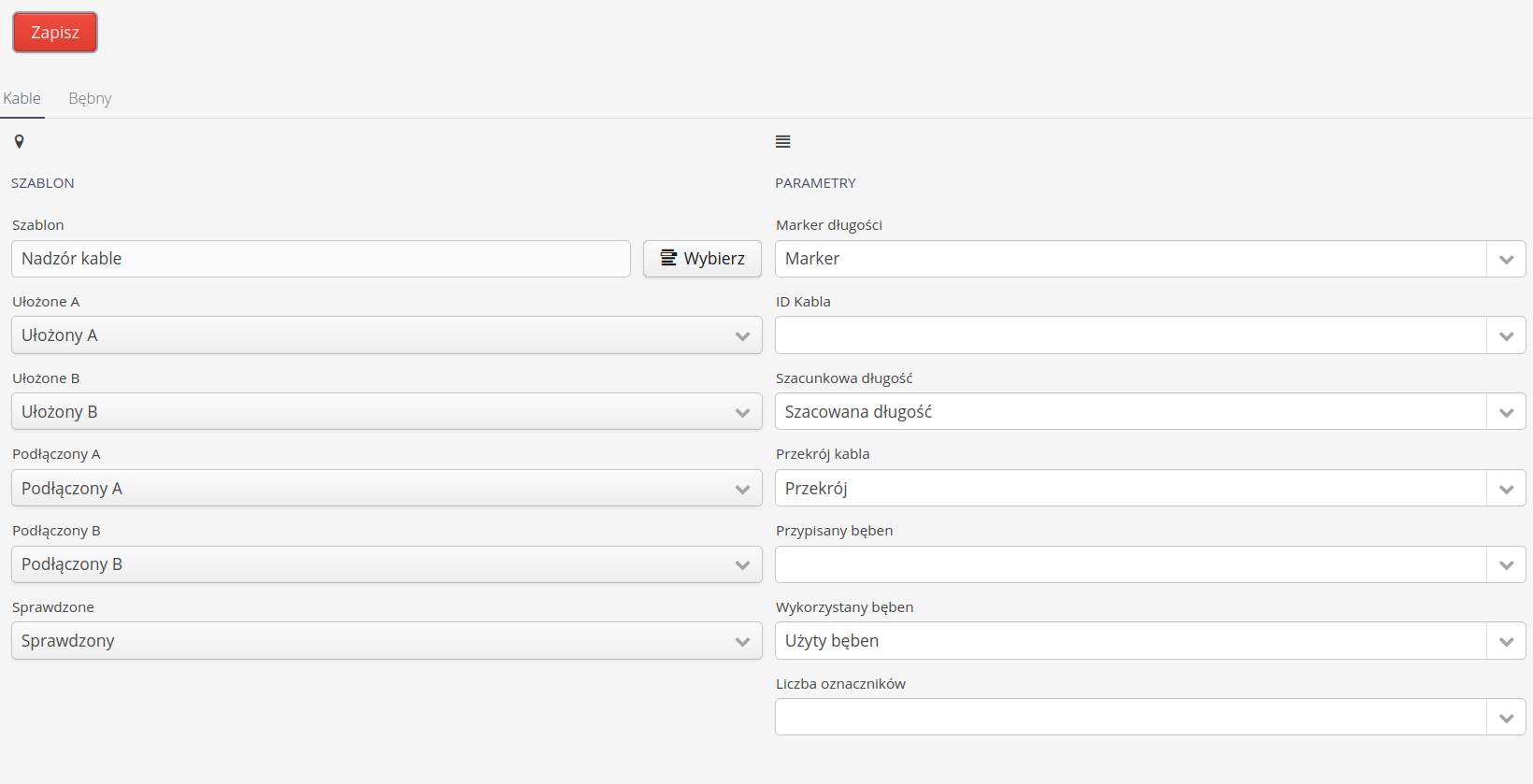

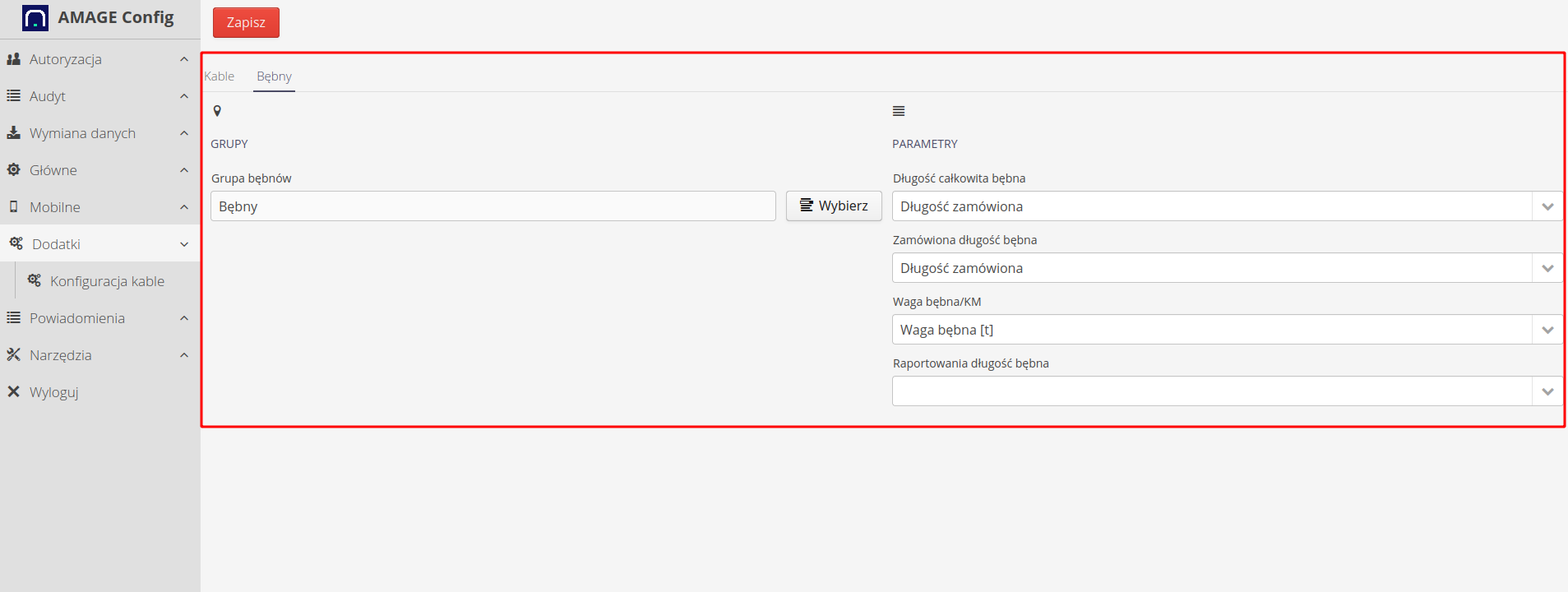

In order for the system to be able to generate appropriate reports specific to drum/cable sections, it is necessary to specify in the configuration which templates and what parameters correspond to the selected sections and parameters.

For cables, we define information about supervision states and parameters that will be used to calculate data/reports.

For drums, we specify parameters such as initial lengths/weights.

| Remember to save the configuration! After saving the data, it will be possible to use it in reports and reports will generate data based on the correct parameters. |

| The import system allows for any data import under any name. Therefore, it is required to indicate key data in the parameters that exist in a given instance. |

IDs for drums

Then we can proceed to the preparation of identifiers for individual drums. In this case, we will use predefined label appearances and configure the labels to store two types of data for drums used in two different areas.

We will use an automatically assigned ID to track supervision of individual drums. This will allow us to report the change in the state of the drum in accordance with the adopted scheme (used, empty, etc.).

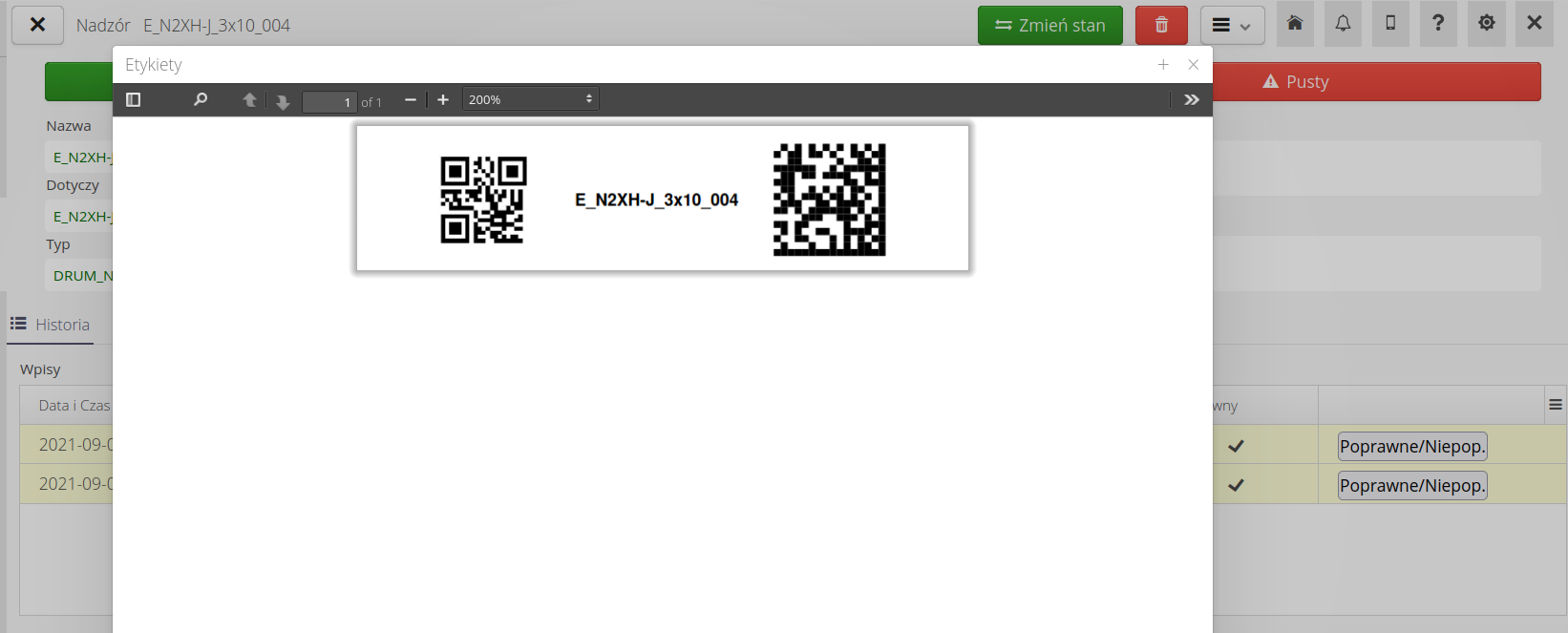

However, we will add an additional, second 2D code (QR Code), which will contain the name of the drum. This name will be used to record which drum the cable was laid from when laying the cable. We do it so that the text known to the user appears instead of the numerical identifier in the parameter view of the individual cables.

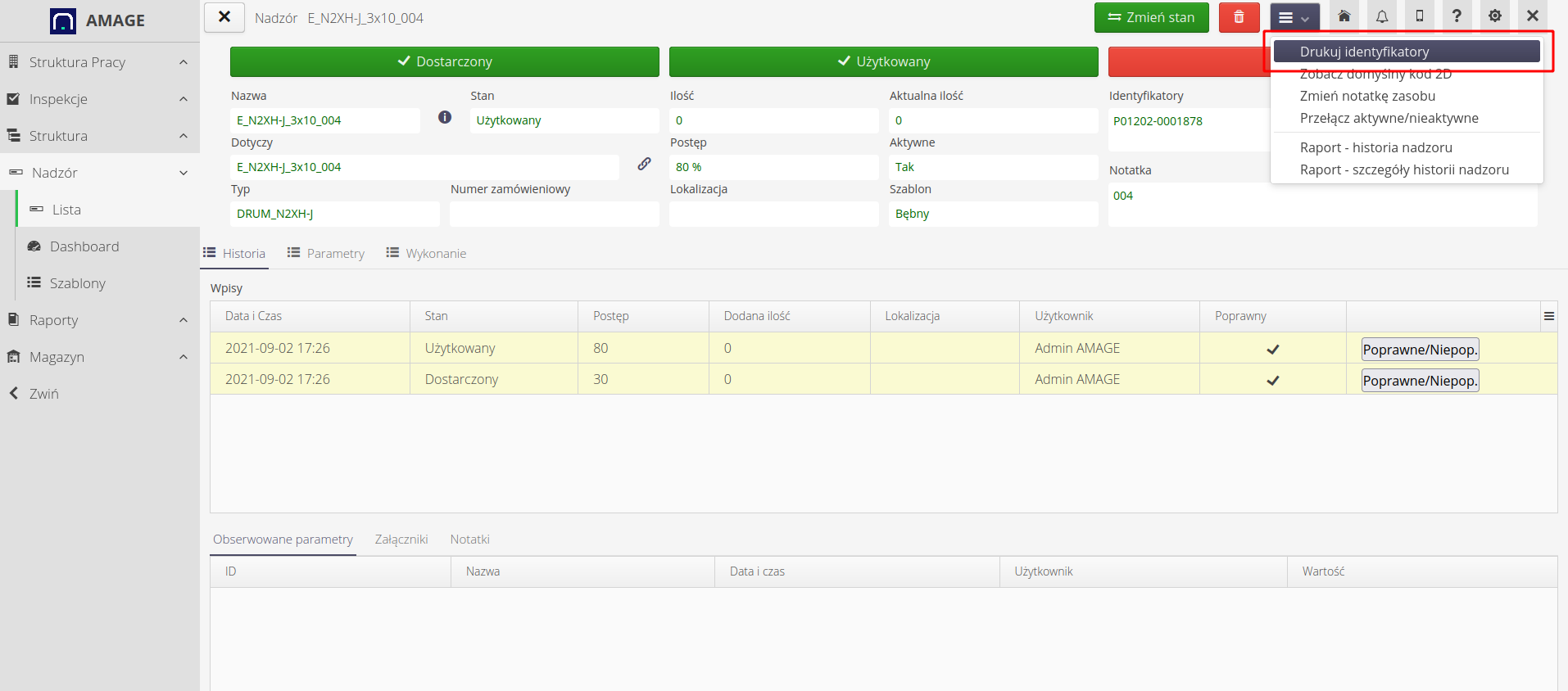

Go to the view of a given drum (you can also generate IDs from a collective list of drums) and select the 'Print IDs' action.

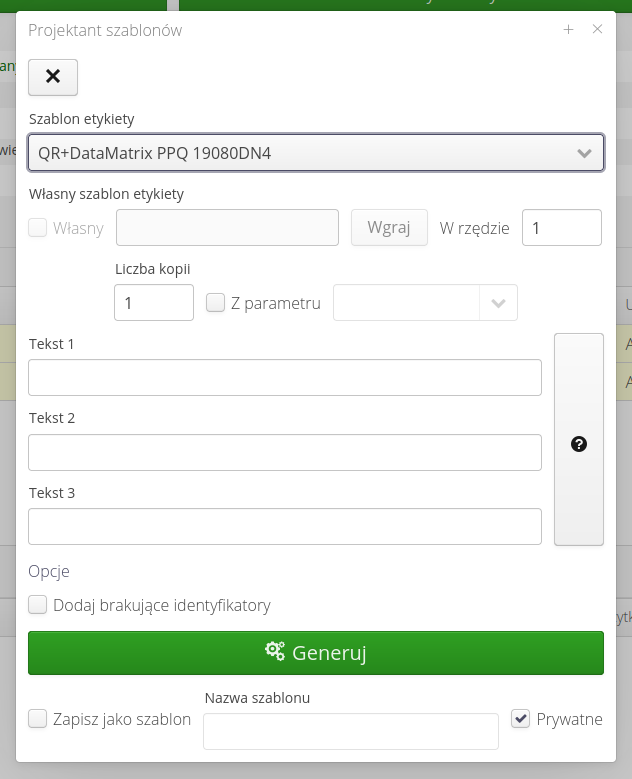

For printing, we choose a QR+DataMatrix template.

| This step is described in detail in a separate tutorial and in the user documentation. This form can be used to freely define the appearance of the labels and the data printed there. |

As a result of this action, we get a label ready to be printed on a label printer. Select the >> button and then "Download" and print the download result on the label printer.

We receive labels that we put on the delivered drums. They can be nailed to the side section of a given drum. You can also print more of the same label and place it in several places on the drum.

Supervision and recording of drum wear

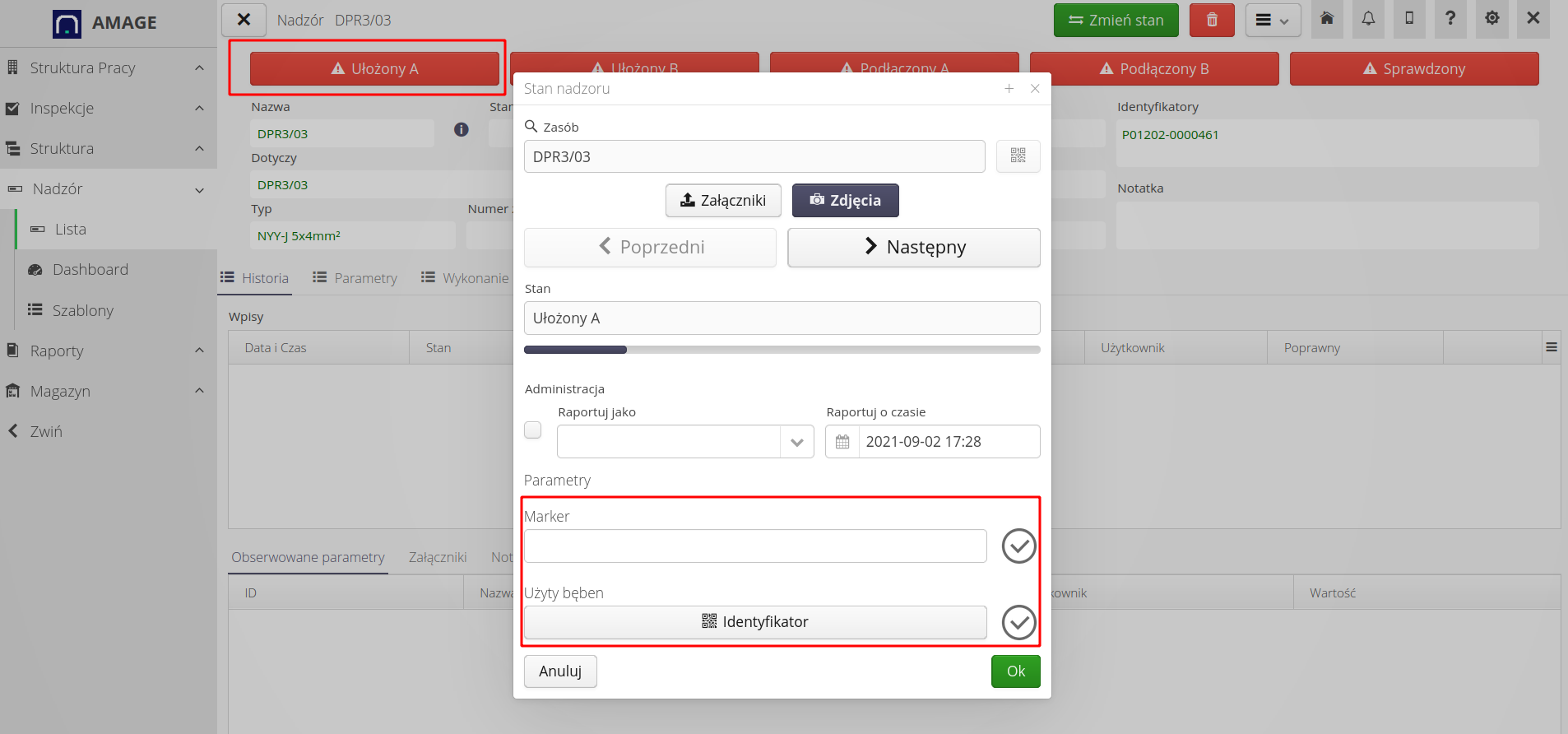

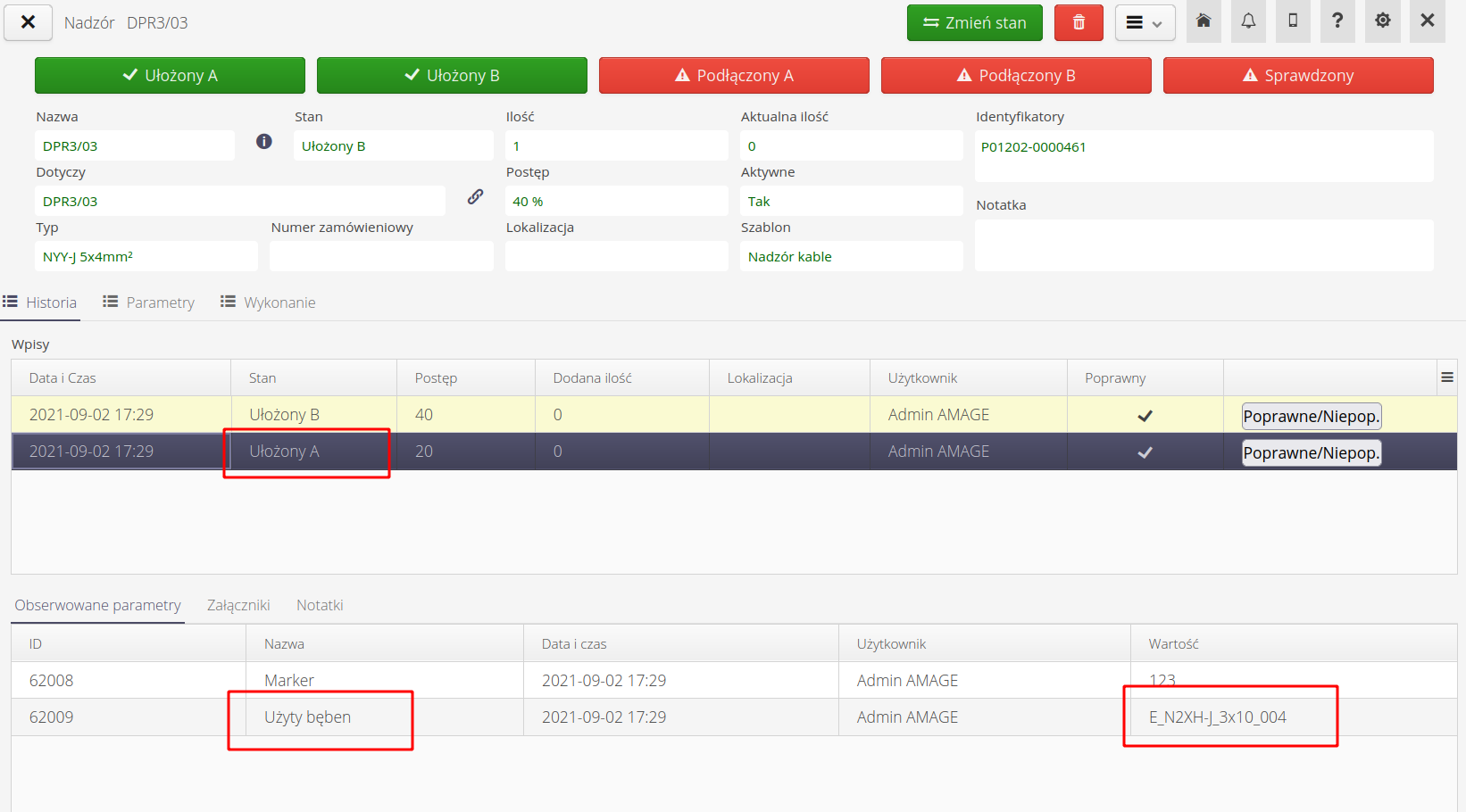

In the definition of cable supervision, we specify that in one of the states, the scanned code of the selected drum should be additionally saved. This allows you to enter (scan) the name of the drum used to lay the given cable, in addition to the cable length marker, when a given condition is selected for the supervision report.

After recording this data in the supervision history for a given cable, information appears which drum was used to lay the given cable.

This data can be used to generate general reports, compare or export information to external systems. The AMAGE system additionally uses this information to generate detailed drum usage reports.

Reporting

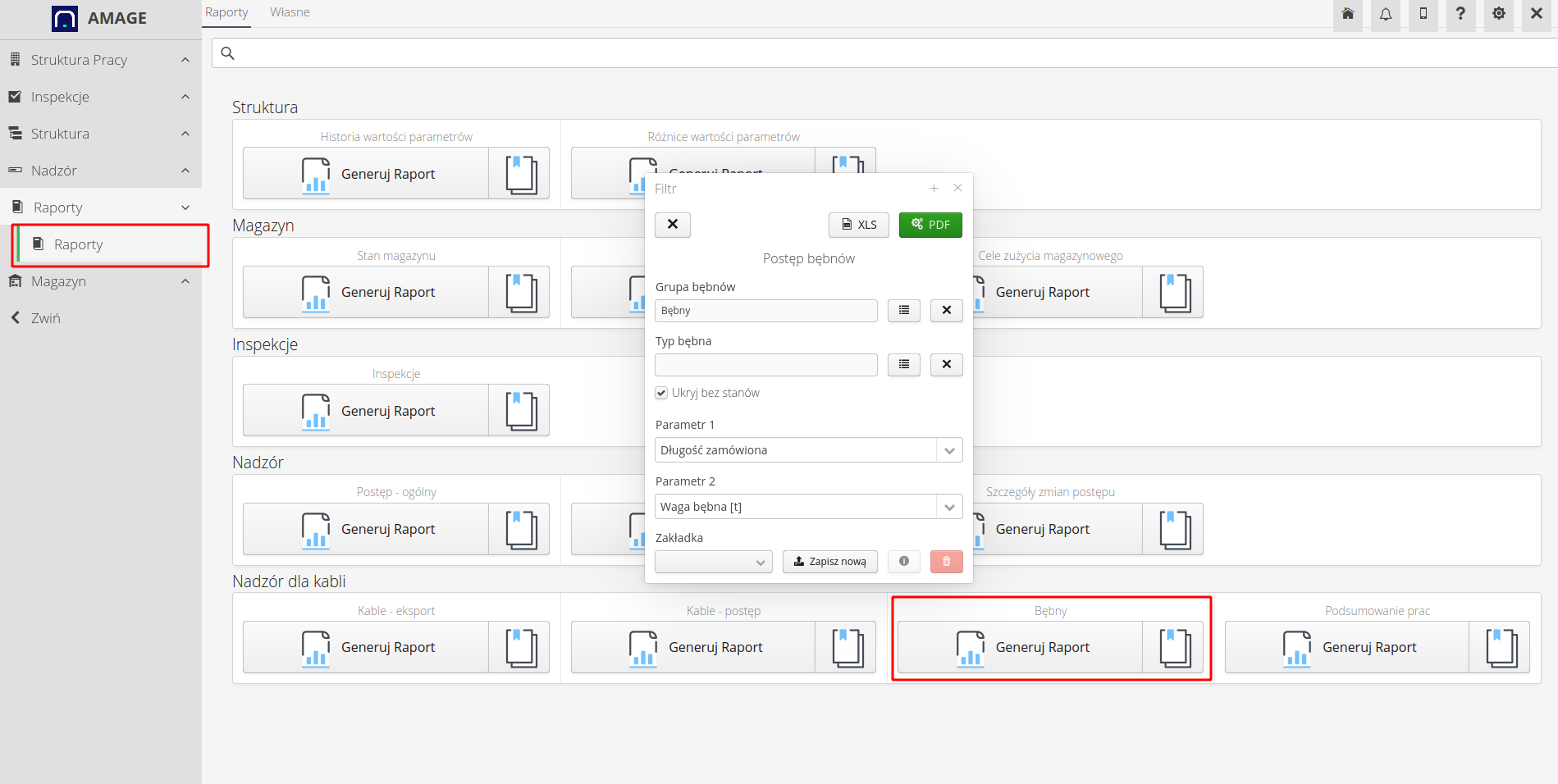

The Drum Usage Report is available in the Report Viewer. Select the Cable supervision section and the Drums report.

Report options allow you to narrow down reports to drums in a specific product group, drum type and add additional visual parameters to the report.

Report generation generates this information as well as collects information about drum usage during cable works.

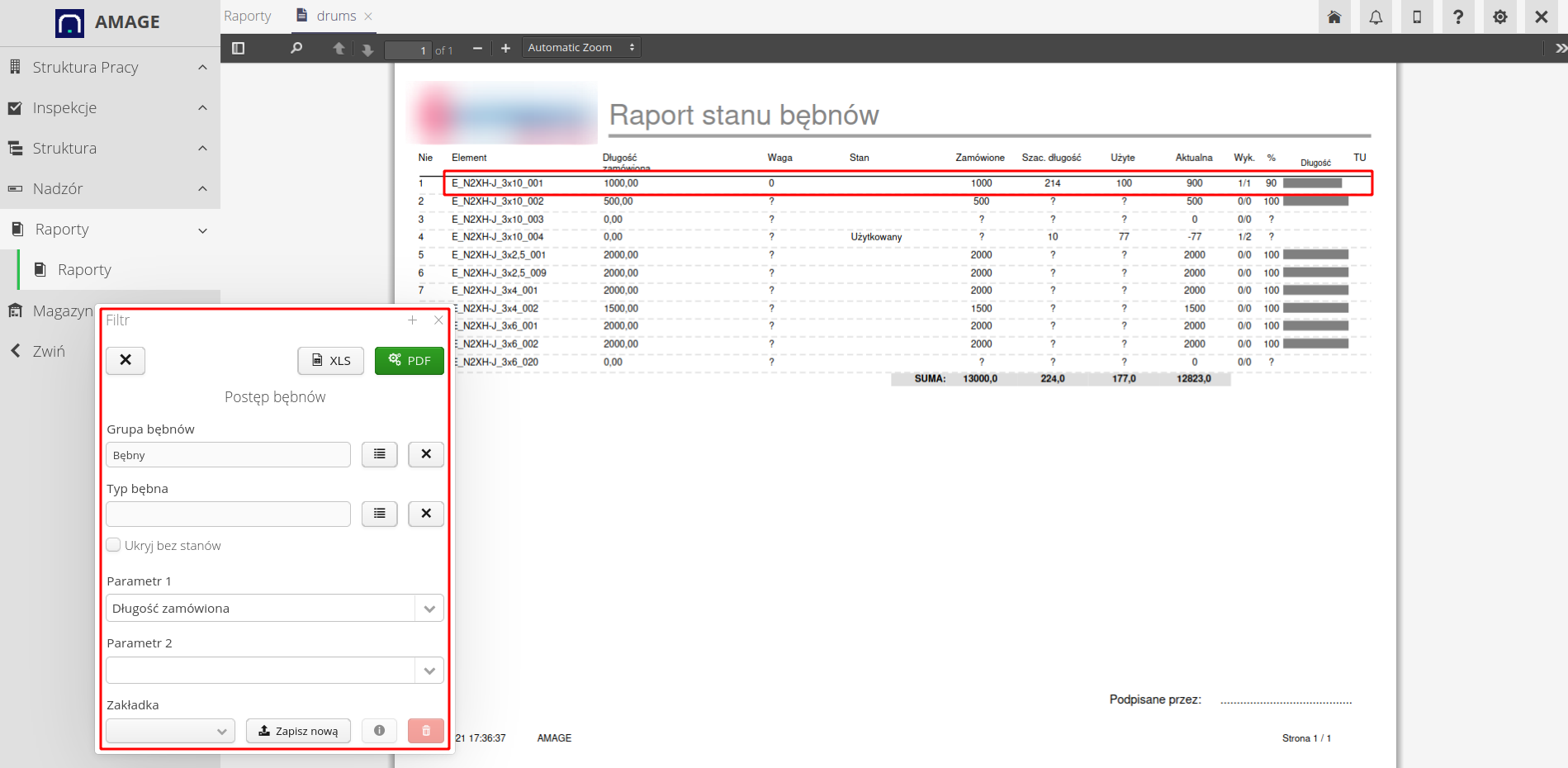

The report presents information on the initial parameters of the drum, wear in relation to the planned length (design) and actual drum wear based on the declared length of the laid cables.

The data contained in the report include:

-

quantity ordered per drum (from imported data)

-

estimated length (from imported data or from supervisory reporting for a given drum, e.g. upon admission to the warehouse)

-

used - total length of the used length from the drum - data comes from all reported cable supervisions, which are calculated on the basis of reported markers on the cable taken from the drum

-

current - the current amount of cable available for use on a given drum

-

Wyk - number of cables that have been assigned to a given drum to be used (*)

-

% - percentage amount of cable on the drum to be used

-

Length - a visual representation of the length remaining on a given reel

-

TU -

To Use- a checkbox indicating whether the estimated length of cables assigned to a given drum will not use the entire length of the remaining cable on the drum

| (*) - in the specialist configuration for cables, we can specify an additional parameter 'Planned reel'. In this parameter, we can save the name of the drum that is planned to be used to lay this cable - this data can come from the design system. If a given cable additionally has a saved designed length, we can provide these additional data based on this data |

| The Howto is based on system version 1.17.0.2 (03.2022) and presents features that may not be available in your system. Ask AMAGE about making this functionality available. |

| Due to ongoing development of the system, some screens or configuration files may look slightly different, but will still retain the full functionality described here. This does not affect the core functionality described in this document. |